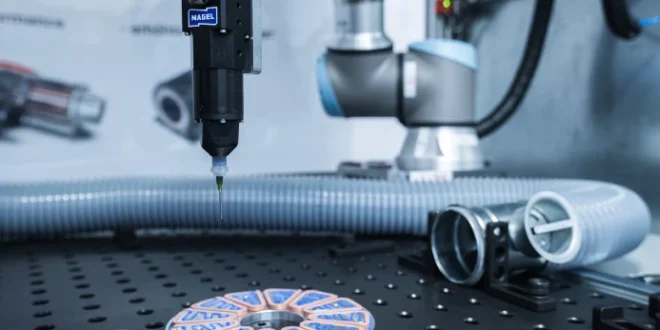

The new NaDos Robot Cell from Nagel Technologies GmbH integrates a UR 10e six-axis robot with features such as plasma pretreatment, calibration sensors, and simulation tools for robotic path planning. The path planning tool allows for quick and intuitive programming of robotic paths — a key advantage for development departments and testing facilities. Its high flexibility makes it an ideal solution for industrial adhesive applications, particularly in e-mobility, where precision and reproducibility are essential.

Plasma pretreatment for optimal adhesion

One of the core functions of the NaDos Robot Cell is plasma pretreatment, provided by Plasmatreat and integrated by Nagel. “By activating the surface, we significantly improve wettability and, consequently, the adhesion of the adhesive,” explains Philipp Schuh, Advanced Robotic Solutions at Nagel Technologies GmbH. “This ensures reproducible quality without the need for rework or cleaning steps.”

Integrated calibration using a TCP sensor (Tool Center Point of the robot) ensures precise tool positioning. An additional precision scale enables exact dosing and calibration of the applied adhesive. Depending on the application, various dispenser sizes are available. The dosing rates range from 0.01 to 1,092ml/min. Additionally, dispensers can be configured for two-component applications with different mixing ratios.

The tool change system allows for the integration of additional dispensers, grippers, screwdrivers, or camera systems. “Our customers appreciate the simple and quick reconfiguration, particularly in testing environments,” emphasises Philipp Schuh. “With minimal effort, various adhesives and processes can be tested without requiring extensive modifications.” The newly developed simulation tool enables users to digitally plan robotic paths in advance and avoid collisions. By simply setting points, the system automatically generates the optimal path and simulates the entire motion sequence.

The NaDos Robot Cell is particularly suited for adhesive applications in e-mobility, such as bonding stators in axial flux motors. Thanks to its six-axis kinematics, it can process both 2D and 3D contours, even in difficult angles or overhead applications. The working area features a 1200 x 800 mm perforated table with variable clamping elements.

Another key advantage of the NaDos Robot Cell is its ease of operation. The intelligent process control system allows productive results to be achieved quickly, even without extensive programming knowledge. This not only saves time but also simplifies operation significantly.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer