Tsubaki’s TSUBAKI Titan Chain, is designed to offer previously unobtainable wear life in harsh applications, like in abrasive and dusty conditions, such as those found in timber mills, stone sawyers or brickworks.

Created by the company’s global research & development team in Japan, TSUBAKI Titan Chain combines the best features of the existing premium GT4 Winner chain with new specifications designed to deliver the ultimate in wear performance.

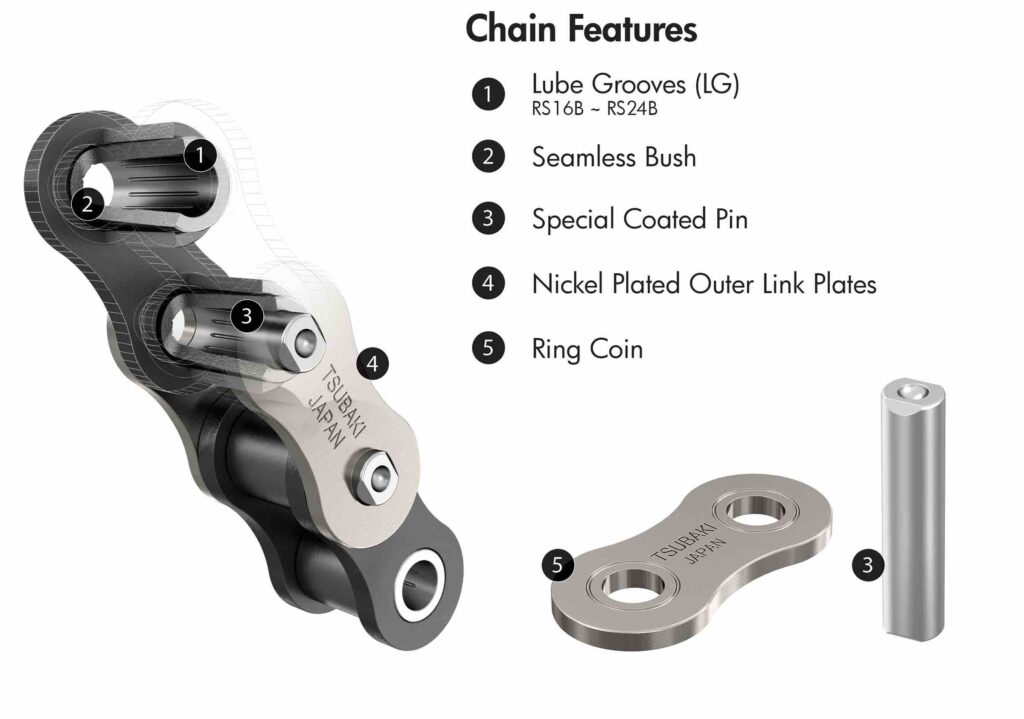

Perhaps the most obvious feature of TSUBAKI Titan chain is the use of seamless bushes that incorporate Lube Grooves. The bushes are precision made and perfectly cylindrical, to ensure the smoothest possible operation which in itself will help minimise wear.

Enhancing this, the special Lube Grooves ensure oil is retained at the very point of contact – where the chain needs it most. This limits the wear between pin and bush, significantly improving the wear life as a result.

The pins have a special coating that provides an extra hard yet low friction surface, thus helping increase wear life further.

As a result of these innovations, maintenance cost and downtime are reduced to a minimum. These factors, plus the reduced frequency of swapping out old chain for new, add up to a significant reduction in the Total Cost of Ownership.

The development team have specified corrosion resistant nickel plated outer link plates for the TSUBAKI Titan Chain, which combined with black oxide inner link plates provide an extra layer of protection against corrosion. Tsubaki has also incorporated its process of Ring Coining the connecting links, which ensures that the chain can be specified up to its full load capacity.

As standard, TSUBAKI Titan Chain is available in sizes 12B to 32B. Additional sizes, multi-strand and attachment options will be available upon request.

TSUBAKI Titan Chain was developed in Japan at the company’s Kyotanabe Technical Centre with input from Tsubakimoto Europe BV. It is seen as part of the Tsubaki Group’s commitment to conserve the environment and reduce the impact of its products and operations by helping customers reduce energy consumption and save cost.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer