In the fast-evolving world of process manufacturing, data is the lifeblood of efficiency, quality and compliance. Yet too often, valuable insights are buried behind siloed systems such as PLCs, SCADA dashboards, historians and field devices that all speak different languages. But there’s now a smarter way to knit everything together, says Tim Ricketts

Unified Namespace (UNS) is a modern data architecture that transforms the way manufacturing companies share, contextualise and use real-time data. But what exactly is a UNS? And perhaps more importantly, how can it help you, the systems integrator, PLC/SCADA programmer, field technician or engineer, deliver stronger results for your process industry clients?

Originating from Walker Reynolds, President and Solutions Architect at 4.0 Solutions, and gaining widespread adoption since 2015, UNS is a real-time, semantic, vendor-neutral, event-driven namespace that represents the current state of a business. It fundamentally transforms the way industries approach data utilisation, promoting a seamless and interconnected digital environment as suggested in part 2 of the ISA-95 Standard.

At its core, a UNS is a structured, real-time data layer that creates a single access point or ,source of truth’, often in a hierarchical format mirroring your plant structure, for every operational and business system in your enterprise. It operates via a publish-subscribe model, for example, using MQTT (Message Queuing Telemetry Transport), where data producers (PLCs, sensors, SCADA) publish to a central broker, and consumers (dashboards, MES, ERP, analytics) simply subscribe to the topics they need. The result? Data flows dynamically, in real time, without brittle point-to-point plumbing.

Real-time data availability

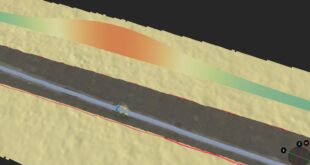

For manufacturers, UNS isn’t just a technical improvement, it’s a foundation for smarter, leaner, more compliant operations. Plant floor data, business metrics and Statistical Process Control (SPC) values are all available instantly in one place, which improves real-time decision-making. Every system is able to access the same data at the same time, eliminating latency and misalignment. Furthermore, UNS supplies live baselines and anomolies can be spotted and flagged proactively. This enables predictive maintenance and better quality control. With a single namespace, you can track production flow and batch issues quickly and deeply, which enables both transparency of your operations and root-cause analysis.

Scalable, vendor-neutral integration

UNS breaks the traditional point-to-point integration model; new tools can be added or removed without disrupting others. It enables legacy and new systems to be integrated through common topics rather than bespoke scripts and allows multiple technologies and suppliers to co-exist, publish and consume data without needing custom interfaces. The result: silos are eliminated and integration through the whole plant (and between plants) becomes simpler. Scalability and adaptability are no longer an issue. New devices or data streams can be added simply by publishing to UNS with no need to rewire everything. It’s open and vendor-agnostic, with no lock-in. End users have the flexibility to choose MQTT brokers, IIoT platforms, or edge/OT tools.

Enhanced security and access control

You also get stronger governance and security. Data policy is centralised and encryption, authentication and audit trails simplify compliance. UNS can help accelerate your digital transformation: unsiloed data enables advanced analytics, AI/Machine Learning, digital twins and smarter workflows.

Structure of a UNS

A typical UNS structures data along familiar lines, for instance: Enterprise /Site /Area /Line /Cell. This leverages the ISA-95 standard hierarchy for intuitive organisation. Alternatively, you could structure around function or process, such as controllers, batch stages, product metrics or quality KPIs, depending on your use case. It operates via a publish-subscribe model, where data producers ‘publish’ to a central broker and consumers ‘subscribe’ only to the topics they require. The data is only made available when the consumer subscribes to the data. This hierarchical topic structure ensures both clarity and scope – your pipe analyst sees just the pipeline data; your Quality Control team can subscribe only to lab and batch quality nodes.

Technology required to implement a UNS

- Edge platform and OT connectivity: devices and PLCs need connectivity, often via edge gateways or SCADA systems that publish data to UNS topics.

- MQTT broker: serves as the central messaging hub for data distribution.

- Middleware or data operations tools: to normalise, transform, contextualise data if needed.

- Event-driven architecture (EDA) framework: the overall design embraces real-time updates based on events rather than polling.

- Governance and security layer: TLS, certificates, access control, topic permissions and audit logging are essential but often overlooked.

Ensure top-level location data management

AGAD Portal, a cloud-based industrial data management solution from Listo, puts the UNS concept into practice. By adopting Walker Reynold’s principles – ISA-95 style hierarchies, event-driven architecture using MQTT, metadata consistency, and open/vendor-agnostic protocols – AGAD enables a true single source of truth for OT data.

Listo has developed a Unified Gateway Server to facilitate enhanced data collection and communication of UNS messages across industrial environments. The Unified Gateway Server will serve as a central component for aggregating, processing and distributing UNS messages within industrial networks. Leveraging common IIoT protocols such as MQTT, the Unified Gateway Server will enhance data exchange efficiency, scalability, and security, ensuring seamless integration with various platforms that meet specific technical standards. This means faster insights, easier integrations, safer access, and the agility to deploy new analytics, AI, or new devices – without significant overhead.

Implementing UNS effectively demands a blend of OT know-how, IT architecture, data governance, security and change management – precisely the kinds of challenges you face daily. Listo integrated SCADA, PLC, MQTT and historians – across food and beverage, chemicals, pharmaceuticals, power, metals and waste. We architect robust, secure, scalable UNS solutions that respect OT realities while delivering modern insights and agility. We guide you through governance, naming conventions, phased rollout and long-term sustainability.

Imagine your next UNS project: seamless real-time data across operations, dashboards that update live, instant anomaly detection, predictive maintenance, AI-ready pipelines – all underpinned by a structured UNS. That is peace of mind for your team and a jump-start to Industry 4.0 for your business.

Conclusion

A UNS is far more than a technology, it is the foundation of truly connected, responsive, efficient process manufacturing. It is a mindshift, from fragmented to federated data, from reactive to predictive operations, and from IT/OT separation to true digital convergence. Without a UNS, every new system or digitalisation initiative risks duplicating effort, increasing complexity and locking the business into brittle integrations. By adopting a structured, real-time data hub, factories become data-driven, not vendor-dependent. UNS empowers systems integrators, PLC/SCADA programmers, field technicians, engineers and decision-makers alike to work smarter – making better decisions faster, reducing downtime, boosting quality and laying the groundwork for advanced analytics and AI. Operators, engineers and executives get actionable insights, not noise.

Tim Ricketts, Business Development Manager at Listo.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer