Significant improvements in measurement speed and accuracy of non-contact colour measurement sensors have led to their increased use in many different production processes, including surface finishing applications, says Glenn Wedgbrow

Surface finishing encompasses a wide variety of processes such as deburring, coating, polishing and texturing. The purpose is to modify a surface to improve specific properties such as corrosion resistance, durability, adhesion or appearance. To ensure high quality standards, measurement of colour is an invaluable technique in surface finishing.

Micro-Epsilon offers a range of colour sensors and measurement systems for use in surface finishing applications – from sensors that recognise and distinguish colours, to systems that measure the colour of metallic components and coated flat glass, helping to ensure the quality and consistency of the final product. Here are some application examples:

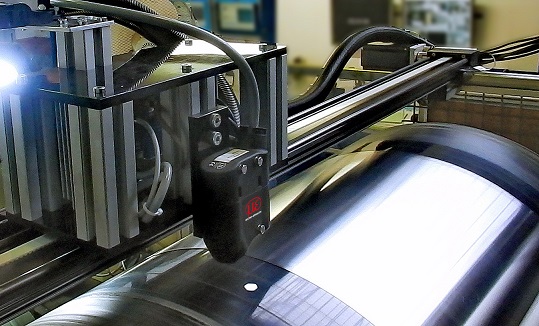

Colour measurement of zinc-coated strip

Steel or aluminium strip material is used to produce punched, bent and deep-drawn components. The steel or aluminium is coated with zinc for refinement purposes, to enhance the appearance and to provide resistance. The zinc is deposited onto the cleaned strip from an electrolyte solution by applying a high electrical current. As well as receiving corrosion- and wear-resistant protection, the strip material also has a defined colour. Reliable testing of this colouring is necessary in order to ensure consistent product quality.

In order to fulfill the high requirements for precision and speed, the colorCONTROL ACS7000 colour measuring system from Micro-Epsilon is used, which recognises colour shades to an accuracy of ∆E < 0.08. Manual, visual inspection is not possible in this area, as a trained human eye can only recognise colour distances up to a maximum of ∆E 0.5. In addition, the colour measuring system must keep pace with production and is able to provide high speed inline measurements. Influences induced by fluctuating temperatures are minimised by continuous referencing. Via an Ethernet interface, these high precision measurement values are directly transmitted and evaluated by a connected production monitoring PC. Should any deviations occur, the plant operator can rapidly intervene, which means waste is reduced.

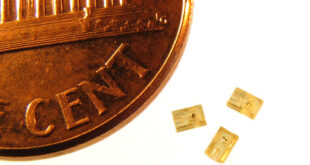

Distinction of shiny screw nuts

In fully automatic machining centres, the reliable distinction of supplied parts is critical. In particular, measurement objects with shiny surfaces place high demands on sensors. Here, colorSENSOR CFO100 sensors from Micro-Epsilon are used to reliably differentiate between glossy nuts made from aluminium and tin. An optical fibre is guided to the measuring point. The high accuracy of the CFO100 sensor then enables the reliable detection of the respective metal and transfers the measured value to the processing machine.

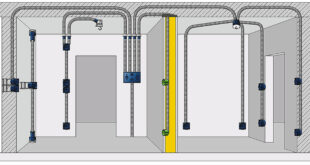

Inspecting the interior coating in aluminium cans

During production of aluminium cans, the inside and outside surfaces are painted with transparent varnish that protects the can from corrosion and prevents any reactions with the filling media. For presence monitoring of the interior varnish, colorSENSOR CFO200 colour sensors from Micro-Epsilon are used which check the presence of the interior varnish using fibre optic sensors.

Colour distinction of aluminium rims

In the automatic inspection of incoming goods, identical colour shades must be assigned reliably in order to be able to match identical colour pairs. For fully automatic recognition of colours, the colorCONTROL ACS7000 colour measuring system is used. It recognises bright and dark colour shades in order to ensure the reliable assignment of relevant colour shades.

Recognition of anti-reflection coating on lenses

Optical surfaces of many lenses have an anti-reflection coating which should reduce surface reflections. These anti-reflective layers must be applied evenly; otherwise undesired colour gradients may occur which might impair the function of the lens. In order to inspect the visual colour impression (green-blue for highly sophisticated coatings) and the coating quality, colorSENSOR CFO200 color sensors are used. Equipped with the A1.1 sensor head (total reflection/angle of incidence=angle of reflection). Due to the high resolution, they detect even the slightest of colour variations reliably.

Colour shade inspection of flat glass

The colour of glass is the crucial and visually distinctive feature of many different glass products. This is particularly true with raw materials based on varying compositions, where continuous and objective control of the colour effect is a decisive factor in consistent, homogeneous quality. Colour sensors from Micro-Epsilon are used in order to inspect glass colours and glass shades in the production process. Combined with an ACS3 transmitted-light sensor head, the ACS7000 colour measuring system detects the exact colour shade of flat and display glasses and then transmits the colour values to the higher-level control system.

High accuracy colour measurement solutions

Using a modulated high power white light LED, the CFO100 and CFO200 colour sensors project a white light spot via optical fibre onto the target surface to be inspected. Part of this light is back-scattered and directed onto a perceptive True Colour detector via the same optical fibre. This light is then refracted into long-, medium- and short-wavelength light components and transformed into L*a*b* colour values. High colour accuracy, good reproducibility, high light power and a fast measuring rate enable the sensor to reliably detect the finest of colour graduations, even in high speed measurement tasks and on low reflecting surfaces. Equipped with optical fibres and focus lenses, the sensor can also be used in tasks where space is restricted, as the sensor head requires minimal space.

The colorCONTROL ACS7000 identifies colours using any of the XYZ; L*a*b*; L*u*v*; RGB and DIN99 measurement definitions (user selectable). The system can be set up to continually monitor a production process and output the colour measurement via Ethernet, EtherCAT or RS422 and can also be taught pass fail/limits and then output out-of-tolerance alarms using digital I/O. The system is therefore suitable for a wide range of applications where colours and shades must be examined on-the-fly and to very high accuracies. Existing applications include automotive paint inspection, colour measurement of car interiors, coloured glass, transparent film and sheet production, printing, packaging, medical technology, food, cosmetics, pharmaceuticals and in the processing of plastics, food, wood, paper, veneer and textiles.

Sensor head solutions for a wide range of tasks

The ACS7000 can be equipped with fibre optic heads for monitoring surfaces by reflection using the ACS1 or ACS2 heads or as a thru-beam transmission sensor, ACS3,for use in colour measurements of transparent objects. A transmitter illuminates a (semi-)transparent measurement object. The receiver records the colour while the controller evaluates it. The spectral measuring procedure enables the measurement of colours, shades, contrasts and coatings at high resolutions.

Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer