Nearly 5,000 active biomass power plants generate over 83GW of electricity worldwide, with 1,000 more expected by 2033, according to ecoprog, the consultancy specialising in the fields of environmental and energy technology. Here, Matthew Slater explores how brushless excitation systems help biomass plants maintain stable voltage, reduce maintenance needs and ensure reliable grid compliance amid this growth

Biomass power plants use organic feedstocks such as wood pellets, agricultural residues and forestry waste as fuel. These feedstocks combust in a boiler to generate high-pressure steam, driving a turbine connected to a synchronous generator. The turbine’s rotational energy is then converted into electrical power by the generator.

These plants can operate as standalone power stations or in industrial cogeneration systems where electricity and thermal energy are produced,

Biomass generators face several challenges that directly impact their operational efficiency and reliability. Fluctuations in fuel, moisture content and energy density can impact combustion efficiency, leading to voltage and frequency fluctuations that jeopardise power supply stability.

Additionally, biomass combustion generates significant ash build-up, residues and corrosive gases that can degrade equipment, increasing maintenance costs and reducing operational lifespan.

The importance of excitation systems

Excitation systems are crucial in addressing these challenges. By regulating generator voltage and providing reactive power support, they supply direct current (DC) power to the generator field windings, creating a magnetic field in the rotor that induces alternating current (AC) in the stator. When instability occurs, such as fluctuating fuel quality, the system rapidly adjusts the DC to maintain stable output.

A well-designed excitation system precisely controls the generator voltage, rapidly adjusting to load fluctuations. It can handle sudden shifts without triggering instability and normally includes features like fault detection and quick corrective actions. This ensures compliance with regulations like the UK’s Grid Code and the Connection and Use of System Code (CUSC) while minimising downtime and reducing maintenance needs in challenging conditions.

These regulations require generators to keep voltages within strict limits and provide reactive power to stabilise the grid, particularly during fluctuations in demand or network disturbances.

By stabilising the generator’s voltage and supporting reactive power, a well-maintained excitation system ensures consistent performance through regular servicing, calibration and testing. This reduces the impact of combustion instability, helping prolong the plant’s operational life and minimise downtime.

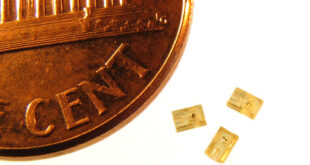

Biomass plants, typically smaller than traditional power stations, have unique design and maintenance demands, for which brushless excitation systems are particularly suitable.

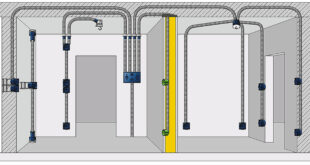

Unlike static excitation systems, which rely on additional components like brushes and external rectifiers, brushless excitation systems are, by nature, more compact. Their smaller size allows direct integration into the generator eliminating the need for bulky external enclosures. With fewer moving parts and minimal maintenance, they offer improved reliability and reduced operational costs, ideal for smaller decentralised applications.

The role of brushless excitation systems

In brushless excitation systems, a rotating exciter mounted directly on the generator shaft generates an AC supply, which is rectified to DC and supplied to the field windings. This design removes the need for brushes and commutators, components that are prone to wear and gathering carbon dust — common issues in static systems that can lead to reduced reliability.

Brushless systems offer fast voltage regulation, essential for smaller plants that must adjust to load fluctuations quickly. Their compact, self-contained design makes them ideal for decentralised biomass stations where space and consistency are critical.

EES provides bespoke brushless excitation system designs to enhance reliability and provide low-maintenance benefits crucial for biomass plants in today’s rapidly growing and diversifying energy sector. The robust design, coupled with the company’s expertise in excitation systems, ensures plants can meet technical requirements, improve performance and extend operational life — all while reducing the frequency of downtime.

With another thousand biomass plants expected in the next decade, stable, efficient and compliant operations are more critical than ever. Brushless excitation systems tackle fuel variability, reduce maintenance and ensure grid compliance, making choosing the right provider essential.

Matthew Slater is director at generator excitation specialist Excitation & Engineering Services (EES)

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer