The human eye is a marvel of nature, but nowadays it is often complemented by the vision of cameras and machines. In warehouse logistics, this technology is allowing operators to validate the logistics process – reducing human errors, tracking parcels and providing real-time feedback for improvements. This is giving businesses the opportunity to see the bigger picture. Mathijs Baron and Lorenzo D’Arsiè report

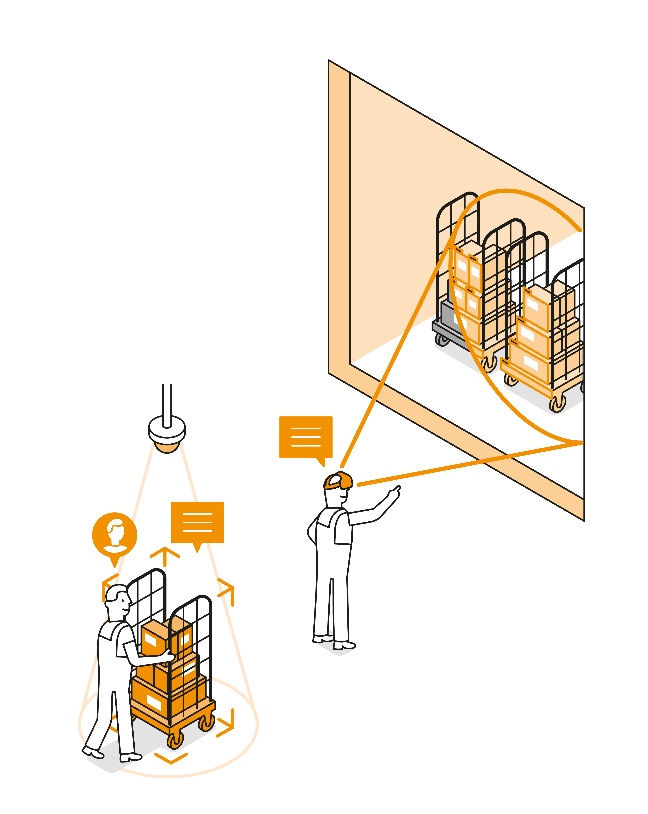

Smart scene understanding is the ability to visualise the exact location of an item within a warehouse at any time. To achieve this, cameras must capture all goods passing through the facility.

Reading labels on inbound goods ready for sorting can be achieved with optical character recognition (OCR) for recording stock keeping units (SKUs), purchase order (PO) numbers, best before dates and more. Similar technology can be used at picking stations to validate a successful sorting process, imaging barcodes to check order completeness. Cameras installed on the ceiling or areas where actions take place provide complete coverage of items in the warehouse. These cameras are smart enough to offer mapping and overlap, enabling the tracking of objects between them. All imagery can then be stored in a central location and combined with other parcel data for total traceability. All this can be done safe and secure and compliant to GDPR and privacy rules.

With this set up, operators can get a complete picture of every single item or order journeying through the warehouse. The benefits of this monitoring are manifold.

Picturing benefits

Image-based tracking reduces manual actions and reasoning in processes like data input or sorting, with the overall aim of minimising human error. However, another important benefit is that it can provide proof of sorting. This level of validation allows operators to identify where problems have occurred during the process.

A centrally stored database of images, such as that provided by Prime Vision’s Smart Store solution, means every action is documented, so records can be accessed to spot mistakes. Operators can identify sorting errors or where an item has become damaged. This can help reduce the number of customer claims by verifying the authenticity of complaints with video evidence.

However, a system shouldn’t just be reactive, it needs to provide real-time feedback to prevent sorting mistakes before an item leaves the warehouse. If an error occurs, an alert should be quickly delivered via a flashing light, alarm or notification to an operator. Staff can then double-check the current location of the item against where the vision system knows it should be. In this way, mistakes are resolved quickly, well before an order is loaded onto the wrong conveyor or delivery truck, saving time and cost.

Getting a better view

The function and technological capabilities of an image-based tracking system are highly flexible depending on the application’s requirements. A recent project for an Italian fulfilment company illustrates this.

Prime Vision was asked to improve a process where products are selected from storage, verified, and prepared for shipment. Historically, this step had been prone to human errors, resulting in mispacked items or incorrect quantities. This translated to delays, additional costs and customer dissatisfaction. However, Prime Vision had cutting-edge technology ready to transform this process by carrying out a double check.

Prime Vision’s ‘Proof of Pick & Pack’ is a game-changing warehouse technology that leverages a combination of cameras and voice recognition systems to ensure the accuracy of the picking and packing process. In this system, forklift trucks or pickers are equipped with cameras that capture images and videos of the selected products during the picking phase. These images and videos are then cross-referenced with a comprehensive reference database containing tens of thousands of product records.

The Proof of Pick & Pack system was a gamechanger for warehouse operations at the Italian fulfilment company. By combining cutting-edge camera technology with a vast reference database and a Pick-by-Voice system, it offered an efficient and error-free solution to the age-old problem of mispacked items and incorrect quantities.

As the logistics industry continues to evolve, embracing innovative technologies like Proof of Pick & Pack is essential for staying ahead of the curve and delivering exceptional service to customers. More than that, the flexibility of image-tracking systems brings benefits to warehouse employees too.

Staff perceive the advantages

Contrary to the story of automation taking jobs, computer vision is proving highly beneficial for warehouse workers, making tasks easier and more attractive. This is especially important for a sector facing a chronic labour shortage.

Monitoring warehouse activities lets businesses identify best practices and new efficiencies. Personal innovations like better sorting routines can be shared with the rest of the team, making work easier for everyone.

Additionally, data from image-based tracking can greatly simplify sorting. Devices such as Prime Vision’s Flow Projector eliminate boring, time-consuming label reading by imaging the label, determining the correct destination and projecting a number onto the item that corresponds to it. Therefore, it is much faster for workers to move parcels to the right place, improving job satisfaction and efficiency.

Intuitive systems that simplify processes expedite training too. Prime Vision engineers have witnessed this first-hand. A new starter at a customer’s site was able to begin work immediately with a Flow Projector as it was quick and easy to provide adequate training. As well as getting up to speed almost instantaneously, staff enjoy collaborating with exciting technology that adds game-like elements to the most mundane tasks. This helps to attract and retain workers, helping warehouses overcome the challenges of the labour shortage.

Seeing into the future

Computer vision and machine learning technology is developing rapidly, and Prime Vision works with academia to harness the latest research and deliver new, innovative image-tracking solutions. By collaborating with the wider computer vision community, the business develops state-of-the-art, customisable systems to benefit any operation.

Validation is critical in any logistics process, but modern image-based tracking goes a step further, enabling operators to take a more proactive approach to enhancing warehouse efficiency and profitability. As well as minimising errors, the technology is allowing humans to excel, augmenting operations with a third person perspective for a deeper understanding of the mise-en-scène.

Mathijs Baron is International Sales & Business Development at Prime Vision, and Lorenzo D’Arsiè, Computer Vision Product Manager at Prime Vision.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer