Hygienic applications, such as the pharmaceutical manufacturing environment, food and beverage sectors and sensitive electronic and automotive environments are demanding ever-increasing levels of air purity from their compressed air system.

In many of these processes, compressed air will come into direct contact with products and there can be severe consequences if air is contaminated with oil or other particulates.

However, says Dr. David Bruchof, Product Manager for oil free compressors from CompAir, investing in oil-free compressor technologies, such as the company’s Ultima, D-series or DX-series models, will help to mitigate the risks of contamination and, combined with intelligent heat recovery, can soon pay dividends.

Oil-free for reduced contamination

There are many benefits to oil-free technology, which can help energy managers make valuable cost savings while improving operational efficiencies too. Whole life costs are reduced, with businesses able to save on the cost of air treatment and oil replacement. Unlike oil-lubricated systems there is no need to purchase equipment that would separate oil from air, such as oil separators, filtration equipment and condensate treatment.

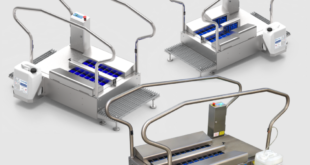

Products in the CompAir range deliver 100% oil-free performance, with fixed or regulated speed options alongside air and water-cooled models including:

D15H (RS) to D37H (RS) single-stage, water-injected models, from 15 to 37kW

D37 (RS) to D160 (RS) two-stage models from 37 to 160kW

Ultima U75 to U160 two-stage, premium efficiency models, from 75 to 160kW

DX200 (RS) to DX255 (RS) two-stage models from 200 to 355kW

The D-series 37 to 75kW range

The range covers air and water-cooled models from 37 to 75kW and is available in both fixed and regulated speeds (RS) delivering reliability, dynamic efficiency, lower operating costs, and high-quality oil-free compressed air.

The CompAir Ultima compressor has been engineered with two highly efficient, permanent magnetic motors that replace the traditional gearbox design. These motors provide efficiencies greater than IE4 and directly drive the airends without the need for a gearbox.

Ultima uses water in a closed-loop circuit for cooling all main components. This allows greater heat transfer and cooling efficiencies, as well as ensuring as little oil as possible is used in the system for assured air purity.

An air-cooled variant is also available; the first ever air-cooled oil-free compressor to offer heat recovery for process water. Up to 98% of heat generated during compression can be recovered to generate hot water at temperatures up to 85oC, achieving cost savings of approximately £70,0001 when compared with the nearest rival models.

Models in the D37 (RS) to D160 (RS) range offer 100% oil-free compression and robust performance thanks to a durable hard coating on the rotors and housing parts.

Models in the DX200 (RS) to DX255 (RS) range feature a state-of-the-art airend that delivers significantly improved efficiency and best-in-class airflow. The premium e-variants with their water- cooled airend jackets enable even greater energy savings.

The range delivers up to eight per cent higher flow compared to industry standards, with up to 7% energy reduction on the fixed speed units and up to 8% on the regulated speed models. The Xe-Series controllers deliver increased control and functionality through an intuitive user interface and provide remote access with any common, current web browser. Variable speed models can sequence up to four compressors without additional hardware to increase efficiency and stabilise pressure.

Seizing other opportunities

With many businesses faced with ambitious sustainability goals, deciding on an oil-free solution provides the most eco-conscious choice too, helping to contribute towards a facility’s green credentials.

For example, heat recovery offers further potential to save money and realise efficiency gains. Around 94% of the energy required to run a compressor is converted to heat, but by using CompAir heat recovery options, this otherwise waste energy can be recovered easily.

Companies consume a lot of energy and cost to generate hot process water, space heating or to preheat water for steam generation. Using CompAir’s heat recovery options, this waste heat can then be re-used to generate hot water of up to 85°C, to be used as process heat in manufacturing operations, for example. With a wide range of retrofit options and no impact on the compressed air supply, companies can often achieve payback on the investment in less than one year.

1. With both the air-cooled Ultima and competitor model operated at 20m3/min, 8bar, for 4,000 hours a year.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer