For applications that require speed and efficiency of movement, wheeled robots can be advantageous compared to legged robots. Their simpler design can also mean lower costs and reduced maintenance. To achieve these benefits, the motion system that powers a wheeled robot must be carefully specified according to the application requirements and environment, taking into account durability, efficiency, and noise. Pradeep Deshmane and Manoj Pujari discuss the motion requirements for wheeled robots

A major benefit of robots is their ability to complete tasks that may be difficult or hazardous for humans to perform. Many such applications rely on wheel-driven robots. From a manufacturer’s perspective they’re easier to design, build and program. For the user, providing the terrain is not heavily obstacle-strewn, wheeled robots can be faster, more efficient, and more resilient. As such, uses for wheeled robots range from pipeline inspection to healthcare environments and even domestic use.

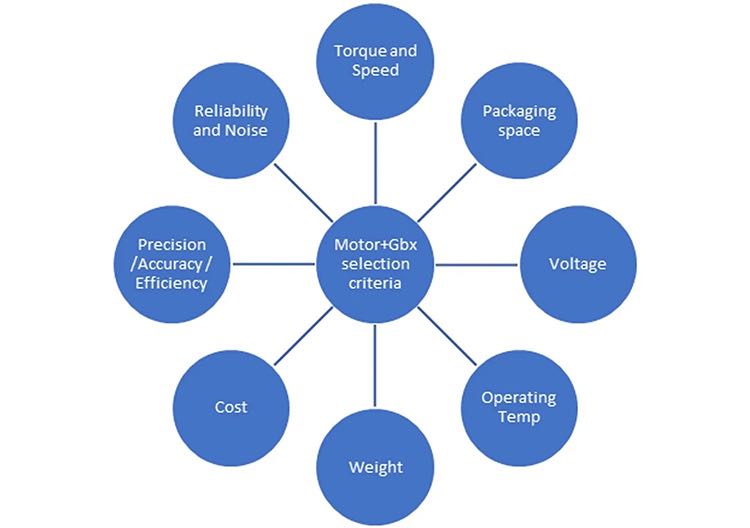

Integral to a wheeled robot is its motor and gearbox system. At a fundamental level, the system has to be compact and lightweight and able to generate the required torque for movement across the specified environment. Frequently used in tough environments, they’ve also got to be highly durable. For many applications, whether military surveillance or in a hospital, noise emissions must also be minimal. Critically, wheeled robots also require high energy efficiency with low current consumption.

For these reasons, coreless brushed or brushless DC motors coupled with compact planetary gearboxes are frequently specified. As the motion system is required to fit within a footprint of less than 40mm diameter, mini motors and gearboxes are required. Despite the compact size, the gearbox output torque must typically handle 4 to 8Nm at speeds between 50 to 150rpm.

Specifying the motion solution

To determine the specification, start by calculating the output torque required. This must factor in the desired acceleration, as well as wheel diameter and mass. Torque requirements necessary to ascend gradients or overcome obstacles must also be added to the equation and finally, friction and efficiency of travel should also be taken into account.

Following calculation of the torque requirement, the wheels’ rotational speed can be determined, and appropriate selection of the motor and gearbox can then be made based on the output frequency. Typically, the higher the operating voltage, the higher the motor’s speed capability.

While sufficient packaging space must be provided for the encoder, brake, motor and gearing, an important factor if the motor stack is enclosed is operating temperature and avoidance of overheating. Motor capacity and heat dissipation techniques may need to be considered in such circumstances to ensure reliability when the robot is deployed in the field.

Motion solution development for a wheeled robot

Portescap recently provided the motion solution for a four-wheel-drive robot. With two pairs of powered wheels, each pair turns in the same direction. It’s vital that the motion system controls both pairs to run at the same speed, otherwise overall robot speed will be reduced and steering won’t be aligned. Unlike differential steering that uses separately driven wheels, this four-wheel-drive solution has a differential steering mechanism that requires only a single motor, which reduces footprint, energy use and cost.

The solution was achieved using a Portescap Brushed DC 35 GLT motor and a planetary gearbox with a 99.8 total gearbox ratio. In a packaging of just 32mm diameter and 115mm in length, the gearbox output torque capacity reaches 8Nm with an output speed of 80 rpm. With a life expectancy of 1,000 hours, the motion system can withstand temperatures up to 125°C. These results provide reliable, durable motion to a variety of wheeled robot applications.

Specialist application engineering

Terrain can be a challenge for wheeled robots, particularly among rocky environments, sharp declines, or areas with low friction. While technology such as tracks with a differential drive and skid steer four-wheel drive are increasingly used, techniques to optimise existing motion solutions can also be deployed to increase durability, efficiency, and reduce noise.

For example, needle roller bearings can be introduced to increase durability and efficiency by avoiding scuffing failures and providing smooth rotation of planet gears. Ensuring the gearbox has the optimum teeth combination with lower torsional forces can also reduce noise, which can be improved with an advanced acoustic simulation to predict noise emission.

To achieve the optimum motion system for a wheeled robot design, it’s crucial that it is specified according to analysis of the application requirements and the environment in which the robot will operate. Portescap’s engineers can provide a range of solutions for robotic motion, with engineers able to create customised designs for precise needs.

Pradeep Deshmane is Principal Engineer – Gearbox, R&D, with Portescap, and Manoj Pujari is Lead Engineer – Product & Development, Portescap.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer