At the end of 2024, the new version of ISO 13855 on the positioning of protective devices on machines was published. The revised version contains amendments and additions to reflect the developments of recent years and the current state-of-the-art. Markus Erdorf, Senior Safety Consultant at Leuze, explains what we need to know about the updated standard

ISO 13855 has been a proven reference for the design of protective devices for more than a decade. Why was the revision necessary?

Markus Erdorf: The last valid version was published in 2010, around 15 years ago. That’s a long time in industrial automation, and a lot has changed in the meantime: Today, we are dealing with more flexible production systems, more mobile robots and new operating concepts. The previous standard could only reflect this to a limited extent. We also looked at the incidence of accidents at work and derived normative consequences from this. ISO 13855:2024 is better suited to current technologies because it provides more precise specifications for the calculation of safety distances and, accordingly, for the positioning of protective devices. It also addresses topics that were missing from the previous standard and adjusts existing values.

What are the most important new features of ISO 13855:2024?

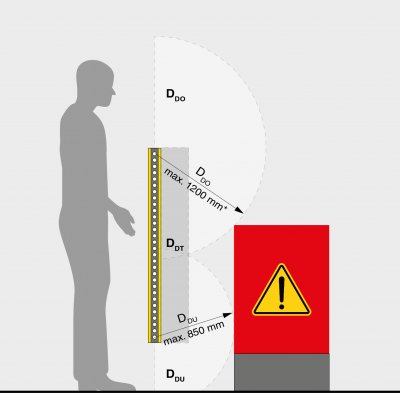

Markus Erdorf: The calculation of the safety distance, previously referred to as the minimum distance, has been revised and extended for the orthogonal, i.e. right-angled, approach of a person. This allows the safety distance to be determined more precisely. Specifically, the range DDS – previously referred to as safety distance C – is now determined on the basis of three criteria: Reaching over, reaching through and reaching under the protective field. The DDU (reaching under the detection zone) has been added and the DDT (reaching through the detection zone) has been extended by a formula. For the parallel approach of a person, the calculation has been simplified by the use of flat-rate values. The Z supplements, which result, for example, from the measurement inaccuracy of safety laser scanners or brake wear on vehicles, have also now been included. Another very interesting topic is ‘distances to safety-related manual control devices’ – referred to as SRMCDs in the standards. The distances must now be calculated to enable installation in a safe position.

The value for DDO is a maximum of 1200mm and results from the ratio of the upper edge of the protective field to the height of the hazard area. The values in the associated ‘Reaching over’ table in ISO 13855 are unchanged from the previous version

The introduction of the dynamic safety distance is intended for the future. This makes it possible, for example, to dynamically adjust the safety distance during robot movements depending on external conditions such as speed, braking distance and direction of movement. It has therefore become somewhat more complex to calculate the safety distance. On the one hand, this means more accuracy, but on the other hand it also means more responsibility for the users of the standard.

What impact does the updated standard have for machine manufacturers?

Markus Erdorf: The Machinery Directive (MD) applies to manufacturers of machinery. This states that only safe machines may be placed on the market. Standards or harmonized standards exist to make this easier to prove. Even though the new EN ISO 13855 has not yet been harmonised, it reflects the state of the art and thus states how machines are correctly safeguarded today. It is therefore advisable to apply the new requirements immediately, regardless of harmonization, as the MRL also references the state-of-the-art.

Where, for example, are the changes in the systems specifically noticeable?

Markus Erdorf: Let’s think about a classic in industrial plants: vertical safety light grids for access protection. In the previous version of the standards, two beam safety light grids were only permitted with a corresponding justification in the risk assessment. The use of these devices is now ruled out, as the distance between two beams has been limited to a maximum of 400 millimeres in order to prevent climbing through. In addition, the value to prevent the light grid from creeping underneath has been reduced from 300 to 200 millimetres. The value against climbing over remains unchanged at 900 millimetres, but these factors mean that at least three-beam safety light grids must be used in future. Manufacturers and operators must pay attention to this when selecting the required safety technology – Leuze offers suitable solutions here with its multiple light beam safety devices in up to four-beam versions.

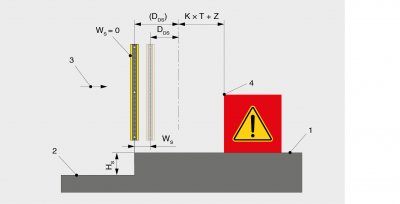

One of the changes: a constant additional distance depending on detection capacity and mounting situation [mm]

The ‘reaching under‘ of vertical protective fields has been included in the standard. Does this increase system safety?

Markus Erdorf: Definitely. The previous version of the standard did not actually take reaching under into account, only the value of a maximum of 300 millimetres of the lowest beam above the reference plane. In this respect, you could easily reach under a protective field with one hand or arm. From now on, the reach for reaching underneath must be determined so that the safety light curtain, for example, can be installed correctly. The now reduced value against crawling under also increases safety.

You also mentioned the subject of acknowledgement buttons, which is now covered comprehensively in the standard.

Markus Erdorf Correct, ISO 13855:2024 now explicitly addresses safety-related manual control devices – i.e. SRMCDs. The term is defined more broadly in the standard, but mainly relates to the installation position of acknowledgement buttons. In the past, it simply stated ‘The reset device must not be accessible from the danger zone’. The distance to an SRMCD, and thus in particular for acknowledgement buttons, must now be calculated. The calculated values may also end the previous discussion as to whether something is unachievable.

The current standard also introduces requirements for safety distances in connection with steps. What is behind this?

Markus Erdorf: All values in the standard for calculating the safety distance refer to a reference plane. This is often the floor on which the person is standing, but it does not necessarily have to be. If there are steps, accessible machine frames or platforms on a machine, this always leads to the question of which of the two levels is the correct reference level. This is now clarified in detail in the standard using several examples. The standard distinguishes between ascent and descent, step height and width and then uses a table to directly specify which surface is the reference level in order to avoid misjudgements.

These are just some of the changes resulting from ISO 13855:2024. Do existing systems now have to be adapted?

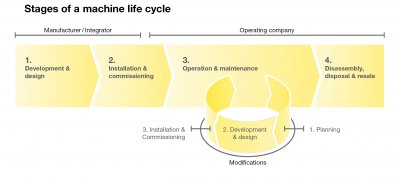

Markus Erdorf: At this point, it is important to distinguish between the manufacturer and the operator. In accordance with the Machinery Directive, the time of placing on the market always applies to the manufacturer. This means that old systems are not relevant for the manufacturer, but all newly built machines are and this applies equally to special machines and series machines. The operator is subject to the current Industrial Safety and Health regulations that require a risk assessment to be reviewed regularly. The state-of-the-art must be taken into account and, where necessary, the safety technology must be adapted. The new version of the standard is state-of-the-art and therefore also relevant for existing systems.

Sustainable machine safety begins with the professional planning of safety systems and extends over the entire life cycle of a machine

Markus Erdorf is Safety Consultant at Leuze.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer