Bruce Parkinson explores the upcoming changes in International Air Transport Association (IATA) transportation regulations and the fact that a 30% state of charge will be required from 2026. In response, the piece discusses the importance of reliable batteries and charging infrastructure in helping MilTech meet these standards

International government and defence organisations have ever-changing portable power and charging requirements. New regulations by the International Air Transport Association (IATA) could cause charging issues for militaries once batteries reach their destination. Additionally, advances in military equipment bring the need for new battery solutions.

Twenty years after introducing an air shipment guideline, which mandated that Lithium-Ion batteries shipped separately from devices must have a state-of-charge less than 30%, IATA has extended the rule to include batteries that are contained within devices.

Until January 2026, government and defense organisations can ship fully charged Lithium-ion batteries inside equipment to ensure they have instantly available power when they reach their destination. However, this new rule means that all batteries will arrive partially depleted and must be quickly brought back to full capacity so they can be rapidly deployed on the battlefield.

Defense organisations operating in remote areas may not have access to AC mains and, therefore, cannot use on-grid, high-power chargers to speed up charging times. Off-grid, operators are often restricted to DC inputs from vehicles or mobile generators — systems not designed to deliver the sustained current required to recharge multiple high-capacity batteries simultaneously.

Multi-bay charging

When using single-bay chargers, operators must rotate batteries one at a time, creating bottlenecks that slow deployment. A well-designed multi-bay system allows operators to replenish several batteries simultaneously at higher currents, ensuring all units have power. For government and defense applications where readiness is measured in minutes and seconds, not hours, this is vital.

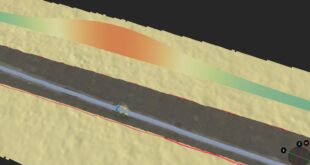

However, engineering these systems is not straightforward. It can be difficult to draw sufficient current from off-grid DC sources, such as vehicles, since they were not designed to support sustained, high-power output. To overcome this, Ultralife launched the UCH0071 six-bay tactical charger, which enables charging rates of up to four amps per bay — roughly twice as fast as many conventional systems. Each bay has push buttons to set the battery’s state-of-charge to 30%.

There are logistical benefits, too. Rather than transporting a surplus of spare batteries to cover recharging delays, personnel can bring fewer units and replenish them more efficiently. This lightens the load and streamlines supply chains.

The importance of batteries

As charging systems evolve, so must batteries. Today, many military and government devices – including advanced radios, sensors and unmanned systems – often require higher current draws than older battery designs can supply. Recently, Ultalife was asked about getting more power out of its UBI-2590 rechargeable batteries, which are commonly used in military communications gear. The result is a version of UBBL13-01 modified to safely deliver up to 15 or even 30 amps compared with the standard 10.

There’s still a place for the traditional solutions. For example, the UBI-2590 continues to serve applications requiring moderate capacity because it balances performance and reliability. For larger-scale power needs, 24-volt batteries that can be stacked together to provide 10kwhrs of storage are ideal.

These units can be combined in parallel or series to deliver higher currents without external protections. This makes them well-suited for vehicle-mounted systems or mobile command posts that require flexibility and robustness.

Efficiency in the field

Capacity and current are important, but so is efficiency and durability. Lithium-ion batteries should be stored in cool, dry conditions at around 15 degrees Celsius. They work best at ambient temperatures, typically between five and 20 degrees. If temperatures are too cold, capacity is lost as chemical reactions slow down. If conditions are too hot, there’s a risk of fire and explosion.

In defense settings, missions can span arctic winters to desert summers — and this brings constant challenges. Therefore, operators must manage charge and discharge rates carefully, deploying batteries designed to withstand a wider operating range. Meanwhile, manufacturers must design power systems with environmental extremes in mind, ensuring critical equipment can continue to function reliably wherever deployed.

Changing transportation regulations and advancements in electronic devices put pressure on both charging infrastructure and batteries. Meeting these demands requires cutting-edge solutions that combine efficient charging, higher-output batteries and rugged designs.

Bruce Parkinson is Applications Engineering and Inside Sales Manager with Ultralife Corporation

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer