Rising energy costs and the need to remain competitive make the steel industry one of the most difficult sectors to work in. For the equipment, this is an arduous environment and this is especially true for the pumps that are tasked with recycling water from the scale pit. When Arcelor Mittal needed to source a spare pump for one of its plants in Spain, the original equipment manufacturer (OEM) could only offer an equivalent model. Turning to Sulzer, the company found it was able to have an exact replacement that was more cost-effective and retained the spares inventory, offering improved reliability and availability.

In this case, a total of four, two-stage scale pumps are situated in a sump that collects water from the descaling process and transfer it to a filtration process before it is reused. Due to the metal debris in the water, the pumps need to be regularly overhauled approximately every 12 months.

However, these pumps are in constant use and the project needed to deliver spare assets that could be designed quickly and installed during a scheduled maintenance window. None of the operational pumps could be taken out of service in the short-term, so an innovative solution was required.

Finding the best solution

The proposal offered by the OEM meant that changes would need to be made to the pump base and the surrounding infrastructure. The additional time and costs associated with this these changes made the offer unacceptable. In a bid to find a better solution, Arcelor Mittal turned to Sulzer as an expert in pump design.

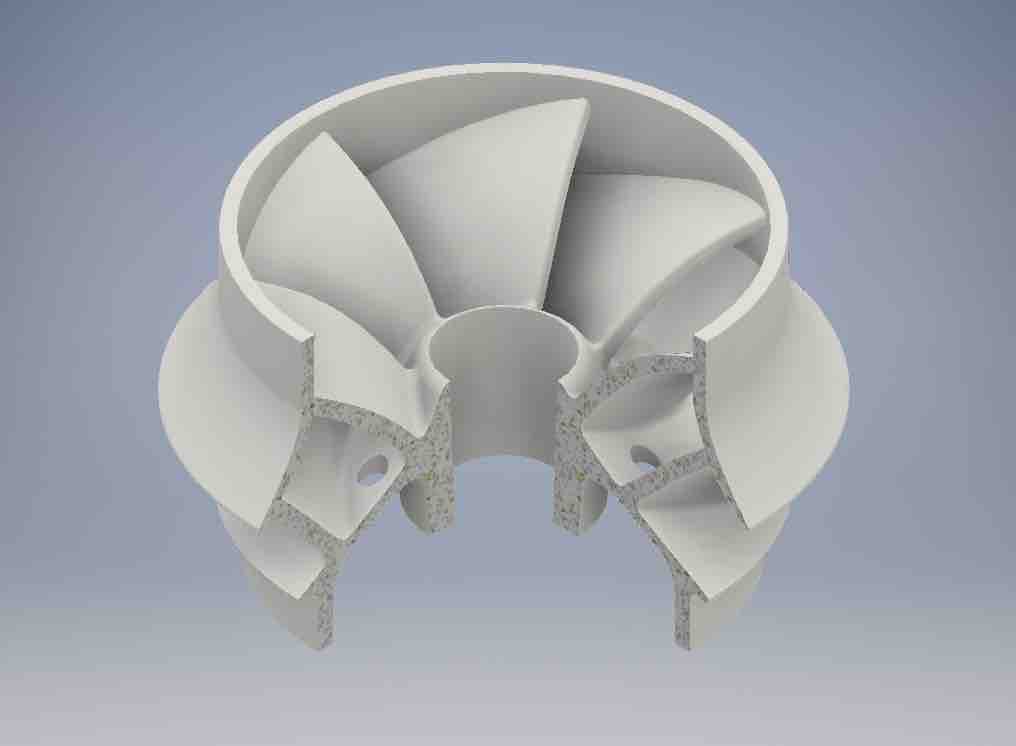

The company offered to reverse engineer the original pump and create a perfect replica, which would be a direct replacement without any need to change the surrounding infrastructure. The customer was impressed with Sulzer’s proposed solution that would deliver a new pump in the same footprint and with the same performance as the existing assets albeit with improved reliability.

Alvaro Ayuso, Head of Services in Spain for Sulzer, comments: “Sulzer was able to work with a single-stage version of the scale pumps that had been previously scrapped, using it as the basis for the design of the replacement pump. In-house designers used 3D laser scanning to draw up the complete pump with identical hydraulics and external connections.”

Simple installation

Having seen what Sulzer could achieve, the customer decided to request the manufacture of an additional replacement pump, which would mean that the existing spares would continue to be applicable and the time for the changeover process would be an absolute minimum.

From start to finish, the project was completed inside nine months. As soon as the factory testing was complete, the new assets were delivered to the steel plant and installed by the on-site maintenance team.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer