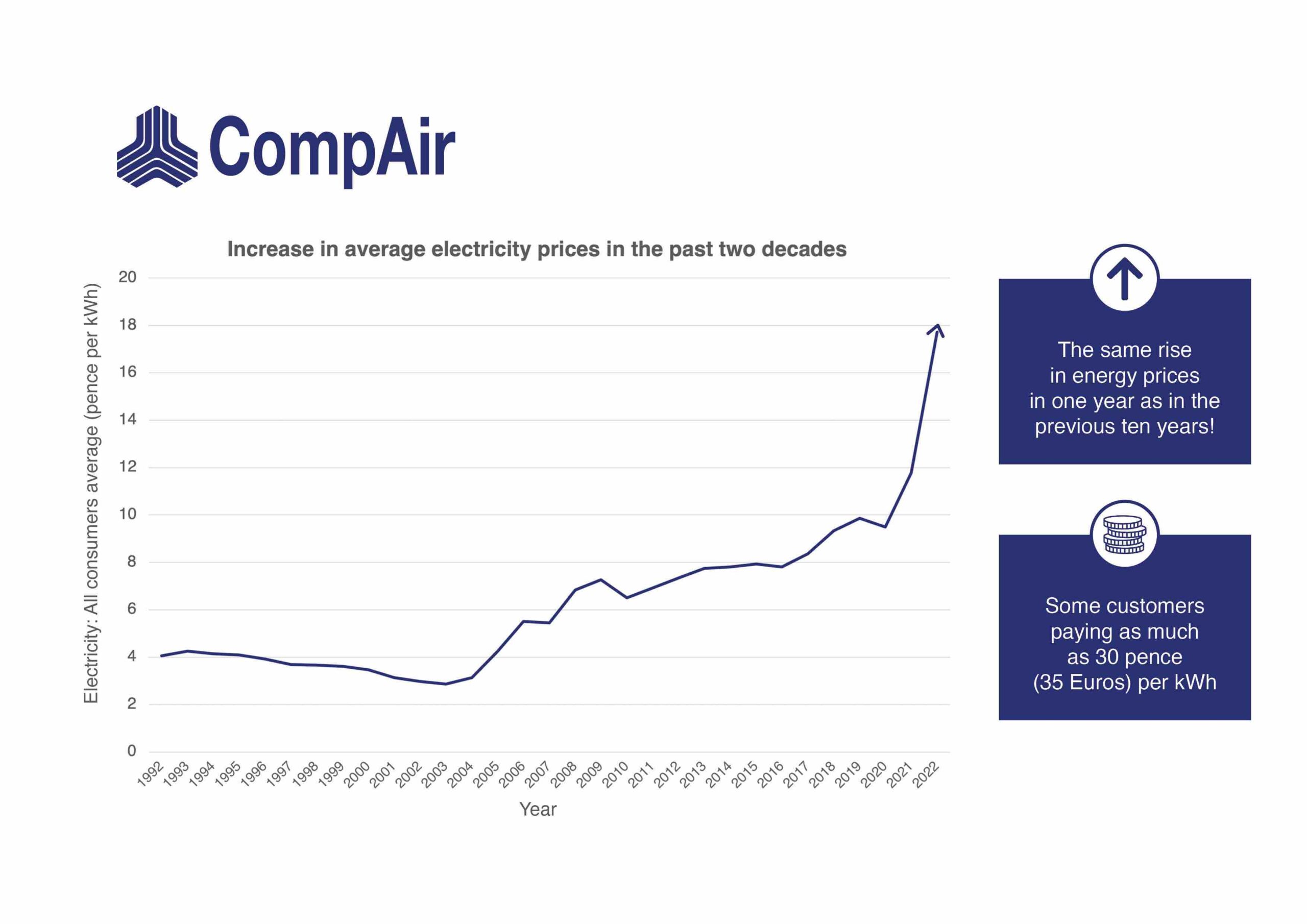

With the global rise in electricity prices, the energy costs of compressed air have increased to as much as 91% of the total cost of ownership, and operators need to urgently review the efficiency of their system says Graham Read

For many years, the industry has used a formula to calculate compressed air cost of ownership, comprising capital investment and installation at 10%, maintenance at approximately 8% and energy costs making up the largest proportion at 82%.

This breakdown has served many customers well, enabling them to make informed choices about how to lower running costs. This is especially the case when considering the cost of capital equipment and the potential payback that can be achieved by investing in an energy-efficient machine.

However, customers now need to re-evaluate the way that they assess their compressed air energy costs as Graham explains:

“Total running costs over the last ten years for a 160kW compressor have more than doubled. Put simply, for every 100,000 Euros spent on compressed air previously, around 82,000Euros of this was the energy costs. Now, this figure has risen to 91,000Euros – with energy costs doubling in the last two years alone.

‘The good news is there are numerous high-performing, energy-efficient compressors available on the market, which can help reduce a site’s reliance on electricity considerably, such as our new L160e-250e range.”

The new L160e, 200e and 250ekW FourCore compressor range, combines best-in-class compressed air efficiency with a small footprint.

The FourCore range offers all the capabilities of an oil-lubricated two-stage compressor, but with only the footprint of a single-stage unit. This compact, two-stage airend uses four gears rather than three, to deliver flexible rotor speed adjustment at both low and high pressures, as well as the best possible performance at different discharge pressures and shaft speeds.

When compared with previous single-stage compressors in this size range from CompAir, the new models are up to 8% more efficient, offering a best-in-class oil-lubricated solution that can help significantly reduce energy costs.

Compared to a 160kW single-stage machine, operating at 7.5bar, the new technology can save up to 12,000Euros a year, providing payback in as little as one year. This rises to cost savings in the region of 18-22,000Euros compared to a single-stage 250kW machine, and a return on investment of well under twelve months in many instances.

Heat recovery options

In addition, integrated heat recovery is offered as an option on the new range.

As much as 94% of the energy required to power a compressor is converted to heat, requiring fans or water to help cool the compressor, at an additional cost. Unless reclaimed, this heat is ultimately wasted to the atmosphere.

At the same time, most companies consume a lot of energy and money to generate hot process water, to preheat water for steam generation or to heat areas of the factory.

By recycling the heat generated from a compressor, businesses can re-purpose this energy to heat water, for space heating, or for application processes in other areas of the installation.

Based on a 160kW compressor, which runs for 6,000 hours per annum, there is the potential to save over 145kW of energy per hour – to offer payback in as little as four months.

Graham continues: “While not every site will have the available capital expenditure to invest in a new energy-efficient compressor, significant savings can still be made by adopting a ‘measure, manage and improve’ approach.

“CompAir offers an air assessment service which looks at all aspects of a compressed air system’s performance, including power and flow data, pressure measurements, leak detection and heat recovery to name a few.

“Using data logging, precise measurements are taken to give a comprehensive overview of energy performance. Suggestions can then be made on potential equipment upgrade or investment, through to simple equipment optimisations and low-cost elements, such as fixing leaks, reducing pressures and switching off compressors when they are not in use.

“The industry is becoming increasing concerned about the substantial increase in electricity prices, and many customers are talking to us about how they can future-proof their compressed air installation to help mitigate for further price increases. By understanding how the cost of ownership balance has shifted, and adopting a system-based approach, it is clear that customers can achieve rapid payback on any investment made.”

Graham Read is, Product Manager Industrial Compressors Europe at CompAir.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer