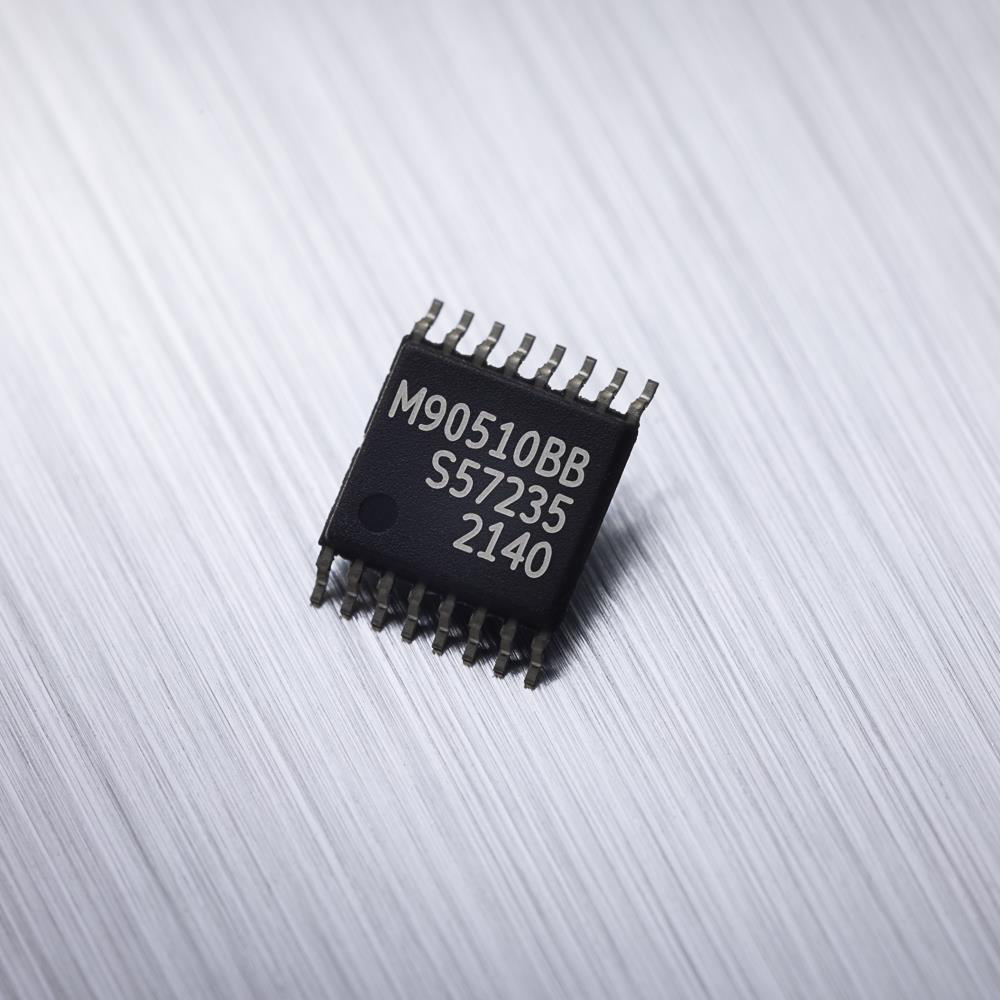

Melexis has developed a new inductive sensing IC intrinsically immune to stray magnetic fields.

The MLX90510 inductive interface IC enables a high-speed resolver minimising the ECU effort required to get best-in-class accuracy under extreme mechanical and electrical conditions. With its superior EMC capabilities, the MLX90510 is perfect for e-motor control, e-brake booster and e-power steering applications.

Melexis has introduced its first open market inductive sensor IC. The MLX90510 offers exceptional accuracy <+/-0.36° at up to 240,000 e-rpm. It is designed for demanding high-speed sensing applications with high accuracy, EMC and safety requirements. It is intended for use in e-motor (e-axle), e-brake booster and e-power steering applications.

“An efficient electric powertrain requires the synchronisation of the stator supply currents with the rotor position. This leads to optimal efficiency and torque characteristic control,” says Lorenzo Lugani, Product Manager Inductive Sensors at Melexis. “Thanks to the digital architecture and rugged design, automotive engineers take full advantage of the MLX90510 EMC robustness with minimal effort on the ECU side, resulting in module cost reduction.”

The MLX90510 offers differential Sine and Cosine analogue outputs and is based on a digital architecture. It comprises Melexis’ patented tracking loop technology. This innovative architecture brings several advantages:

The system propagation delay is trimmed to 0ns with a maximum of ±120ns residual variations over the entire operating temperature range.

Input offset compensation and zero output-angle position adjustment are performed within the IC, lowering the effort on the ECU.

The three-phase-based coil design simplifies linearity optimisation.

Decoupling between the input and output enables unprecedented EMC performances. It also ensures stable output amplitudes independently from the airgap-related input signal strength.

The linearisation feature, with up to 16 calibration points, deals with the non-linearities of challenging sensor modes like side-of-shaft.

The MLX90510 works in combination with a set of PCB based coils whose scalable design can be easily adapted to the number of pole-pairs of the motor. Supporting multiple sensing modes for both on-axis (end-of-shaft) and off-axis (side-of-shaft or through-shaft) operation, the IC maximises flexibility in inductive coil designs to serve the most demanding mechanical constraints. With its overvoltage and reverse polarity protection (±24V on the supply and ±18V on the outputs) the MLX90510 features excellent robustness against electrical challenges. In addition, the sensor is AEC-Q100 qualified for extended temperature operation from -40°C to +160°C. With full adherence to ISO 26262 ASIL C functional safety guidelines, the MLX90510 supports up to ASIL D system-level integration.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer