The new facility was opened by Sir Alan Duncan MP, Minister of State for Europe and the Americas and Member of Parliament for Rutland and Melton.

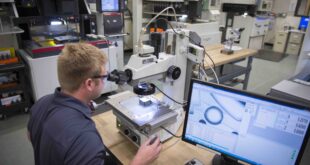

The new 10,000 square foot facility is home to a state of the art workshop and research laboratory that will be used to develop advanced composite processing technologies and automated production techniques for Surface Generation’s clients, which include some of the most advanced automotive, aerospace and consumer electronics manufacturers in the world.

The facility will also be used to experiment with new technologies including graphene, 3D printing and nanocomposites, which have the potential to significantly improve the cost, quality and throughput of high volume composite component manufacturing.

Seven engineers and technicians will work at the facility initially, and Surface Generation plans to recruit 12 more people to its research and development team as part of its expansion plans over the next two years.

Ben Halford, Chief Executive at Surface Generation, comments: “The opening of this facility is a major milestone for Surface Generation. We already help major blue chip organisations find new ways to manufacture composites so that they can be stronger, lighter and more efficient. This new facility provides the environment we need to expand that work and apply our processes and approach to larger and more complex components.”

Sir Alan Duncan MP comments: “Surface Generation is a small business exporting globally and making a big impact around the world. It is turning a small corner of Rutland into a centre of excellence for advanced manufacturing and composites research, creating high value jobs and revolutionising how cars, aeroplanes and electronic devices are built.”

According to market research group Lucintel, the global advanced composite material market is expected to grow by more than eight percent a year over the next five years, to reach an estimated $5.2 billion by 2022. It says that increasing demand for lightweight materials in the aerospace and automotive industries are among the major drivers of growth in this market.

Surface Generation has developed PtFS, a patented advanced manufacturing process that enables manufacturers using compression and injection moulding applications to adapt heating and cooling levels in real-time to meet the exact requirements of each part. It is used by global automotive, aerospace, energy and consumer electronics manufacturers to improve component production quality and throughput.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer