A pioneering project aims to convert air-polluting diesel engines due for scrap into renewable power storage units that can charge electric bus and lorry fleets.

The research is being carried out by the University of Nottingham with support from Volvo Trucks.

While diesel engines are still viewed as economical and efficient power sources – particularly for long distance, commercial vehicles – tough emission standards are increasingly forcing older models off the road.

“What can be done with end-of-life engines is an open question,” said Professor Seamus Garvey, lead investigator for the Faculty of Engineering, University of Nottingham. “One option is to melt them down to recycle the steel, but we propose to explore another possibility – re-task these engines to become machines that compress and expand air to store and release energy.

“Power is increasingly being generated from renewable sources that are intermittent by nature – chiefly, the sun and wind. How to store that off-grid energy for use when needed and not just when generated is a pressing issue to solve.”

Batteries are highly suited to energy storage where high powers are required over relatively short periods and their place in future cars, buses and vans is already beyond question.

Absorbing and dispensing steady power

However, for absorbing and dispensing steady power over timescales of many hours, different technologies are better. Compressed Air Energy Storage (CAES) is one leading alternative.

Established CAES facilities use underground caverns to store pressurised air. When electricity is needed, that air is heated and expanded in an expansion turbine, driving a generator for power production.

Such systems can potentially deliver very low-cost storage, but they depend on finding suitable geological locations and the economics are only good at large scale.

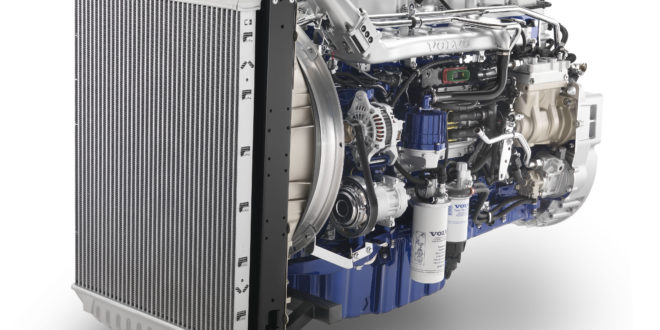

The proposition being explored by Volvo Trucks and Nottingham University is to transform existing engine hardware (the engine block, crankshaft, conn-rods, pistons and crankshaft bearings) into effective reversible compressor/expander machines, at relatively low cost per unit of power rating.

These machines compress air to put energy into storage or expand stored compressed air to release the energy again.

One target application for these machines is at charging stations for fleets of electric buses and trucks.

“The UK would be very nicely catered for beyond 2030 if we had ~50GW of rated power in energy storage facilities. Each individual truck engine would form the low-pressure stage of a three-stage 250kW compression/expansion train. Thus, in theory we could see up to 200,000 truck engines repurposed to drive that level of power.” said Professor Garvey.

The work is at a very early stage. Re-manufactured engine hardware from Volvo Trucks is being gifted to the University where engineering researchers will adapt the parts and incorporate them into new compression/expansion machines. The project will run until August 2019.

Commenting on the partnership, John Comer, Head of Product Management, at Volvo Trucks, said: “It is always great to be involved with universities, especially in the UK, that are working on research projects that meet the company’s ethos of ‘driving progress’.”

The innovative machines will form a part of the “High Performance Compression and Expansion” laboratory at the University of Nottingham which is one key element of a £60m capital project in the Midlands called Energy Research Accelerator (ERA). ERA involves the Universities of Birmingham, Warwick, Nottingham, Leicester, Loughborough and Aston, as well as the British Geological Survey.

The University of Nottingham is an international centre for energy research and an institution committed to sustainability.

The university recently announced it will completely remove any financial investments in fossil fuels within the next 12 months.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer