The additive manufacturing machine targets a wide range of users in manufacturing and many other commercial and business applications, as well as being ideal for educational purposes and at home for anyone who wants to design and build things quickly and at low cost.

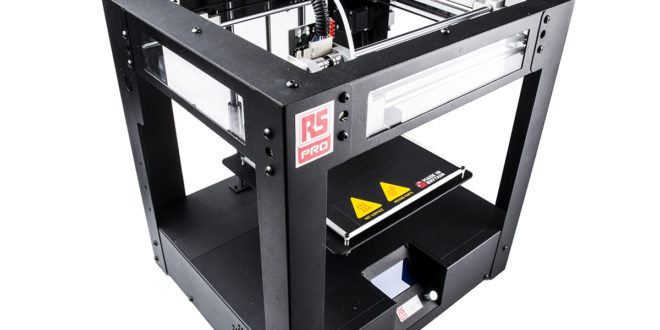

The combination of power, speed, precision, efficiency and multitude of features make the RS Pro iTX 3D printer one of the best in its class.

Along with all RS Pro 3D printers that leave the factory fully constructed, the iTX is made in Britain and is ready to use straight out of the box.

A key element of the machine is its upgradability: the high-quality machined parts and circuit boards are designed to be easy to replace and/or upgrade in a matter of minutes.

All RS Pro 3D printers are open-source designed, which means they can easily be customised by advanced users and enthusiasts alike.

In particular, the iTX’s RS Pro VariBLOCK head unit offers future-proofing, as it is easily interchangeable and upgradable to other extruder head systems, allowing the machine to use various other materials as they become available.

Hot-end and filament extruder

In addition, all serviceable parts including the printer’s hot-end and filament extruder can be easily maintained.

The machine uses the Fused Filament Fabrication (FFF) 3D printing process and comes with a fully heated build plate, handling temperatures in the 50 to 100°C range.

The printer also features a metal-gearbox-controlled filament extruder system to deliver maximum power and reliability.

The extruder is designed for 1.75mm filaments and is capable of printing a wide range of materials including ABS, PLA and PETG.

Other key specifications include: nozzle size options including 0.2, 0.3, 0.4, 0.5, 0.8 and 1.0mm; build volume of 8000cm3 (200 x 200 x 200mm); and a wide selection of layer resolutions from 0.8mm for fast printing, down to layers as small as 0.08mm (80 microns). Coming with a strong steel-powder-coated frame construction, the printer has dimensions of 450(H) x 535(W) x 370(D)mm, expanding to 550(H) and 535(W) when fitted with the spool holder and umbilical wire.

Integrated and fully upgradable PC computer

Another key feature of the printer is its integrated and fully upgradable PC computer, which is based on an AMD Kabini A4 quad-core processor, along with an AMD Radeon graphics card, Ethernet networking, 8GB of upgradeable memory, and an upgradeable 500GB SATA hard-disk drive.

The integration of a PC into the machine enables a number of accessory upgrades, such as adding a webcam or other networking and remote-access capabilities.

Also available separately from RS is a safety-compliant cabinet system that has been designed especially for use with the printer. The RS Pro iTX is shipping now in the EMEA and Asia Pacific regions.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer