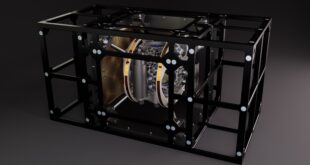

Kollmorgen introduces the P80360 stepper drive, the latest addition to the company´s flagship P8000 stepper platform.

Like other drives in the series, the P80360 incorporates innovative stepless control technology to deliver smooth, quiet motion and optimal performance across the full speed range. Additionally, the P80360 stepper drive offers closed-loop position control and is fully programmable, enabling servo-like versatility, precision and repeatability in a stepper drive.

In addition to open-loop stall detection, the P80360 drive offers the ability to track load position via encoder feedback and automatically correct for any overshoot or undershoot errors. Closed-loop position control is useful, for example, in systems where gearing, couplings or heavy loads result in compliance that can cause motor missteps. By correcting for these position errors, the P80360 actively minimises the risk of scrap or equipment damage. This feature has the added benefit of improving efficiency, so the motor does not consume as much electricity and runs cooler.

The P80360 drive is fully programmable via an intuitive graphical user interface and programming language, available within the Kollmorgen Space software package offered as a free download on the Kollmorgen website. Using these tools, engineers can create simple point-to-point movements as well as linked motion sequences with ease. The versatility and functionality of the P80360 programming software eliminates the need for an external PLC or indexer to perform single-axis motion control, reducing overall system cost.

Kollmorgen Space software also includes a Motor Wizard that enables users with Kollmorgen motors to get their machines up and running faster, requiring only input of the initial profile velocities and acceleration times.

All P8000 series drives are backed by Kollmorgen´s world-class support and expertise, from motor and drive selection and sizing to assistance with setup and troubleshooting. All drives feature CE, RoHS and REACH certifications.

The P80360 stepper drive can be used with all stepper motors with phase current up to 3.0 Arms. It is ideal for labellers, indexing tables, CNC machines, XYZ gantry systems such as 3D printers, packaging, medical lab equipment, pumps and many other applications requiring simple point-to-point movements as well as linked motion sequences.

“The newest drive in our P8000 series is a game-changer for engineers looking to achieve the greatest precision and control in a stepper system,” said Ross McMillan, vice president of engineering at Kollmorgen. “We´ll be introducing even more stepper drives with exciting feature sets in the near future, so stay tuned.”

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer