Ex-stock or custom Belleville washers in a complete package from Lee Spring are often used to solve vibration, thermal expansion, relaxation and bolt creep problems.

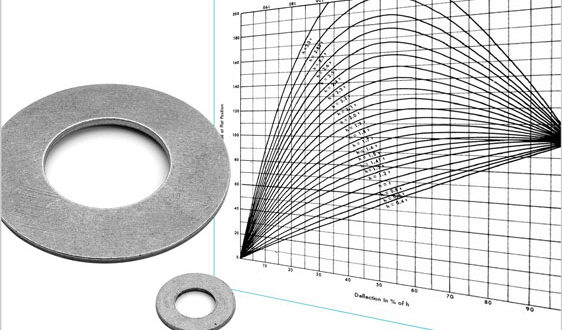

Their conical configuration enables them to support high loads with relatively small deflections and solid heights compared to

helical springs.

Belleville washers may also be used as locking devices in applications with low dynamic loads.

Belleville washers are useful for adjustments because different thicknesses can be swapped in and out and they can be configured differently to achieve essentially infinite tunability of spring rate while only filling up a small part of the technician’s tool box.

They are ideal in situations where a heavy spring force is required with minimal free length and compression before reaching solid height.

Some of the advantages of Belleville washers include: high load capacity in a small space which is not possible with ordinary coil springs, thus affecting the important economics in housing materials.

The ability to achieve linear or non-linear regressive load deflection characteristics while they can compensate for different expansion rates in a joint and still

maintain a high tension, or can act as a shock absorber or perform a dampening function.

It is also valuable that deflection and load characteristics of Belleville washers can be changed by stacking these

washers in series, parallel, or series – parallel combinations.

Lee Spring Belleville Washers are manufactured from 300 Series Stainless Steel. This alloy offers good corrosion resistance for most applications.

Additionally, Lee Spring Belleville Washers are passivated in accordance with specification ASTM A967 to remove contaminants and further improve resistance to corrosion.

300 Series Stainless Steel is slightly magnetic and is recommended for any applications where the temperature is below 260°C.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer