The arrival of a front-loading, aqueous washing and rinsing system from Turbex at the Hampshire production facility of leading UK pump manufacturer Selwood has improved dramatically the efficiency with which machined castings are washed in preparation for assembly.

Two rotating-drum machines, also aqueous and supplied by Turbex 20 years ago to supplant a trichloroethylene cleaning process, have been replaced by a new AC-1.7-2 twin-stage machine.

The old equipment had served well, but its effectiveness was diminishing through age and an inability to maintain water temperature sufficiently high to activate the detergent adequately.

A batch of 12 to 15 castings for the assembly of one pump used to take 40 minutes to clean and sometimes they would have to go back in if they were still soiled.

The new Turbex industrial washing machine can process five such loads placed in four rectangular stainless steel stillages in 45 minutes, representing a five-fold cleaning efficiency uplift.

Valuable pump build hours in the six production bays are no longer lost and delivery lead-times have consequently improved.

With Selwood’s reputation for reliable and robust pumps, it is important that its castings are clean before assembly to ensure correct functioning of the products.

The fine swarf generated when machining cast iron, together with coolant residue and grease, must be removed completely such that none is visible or detectable by touch.

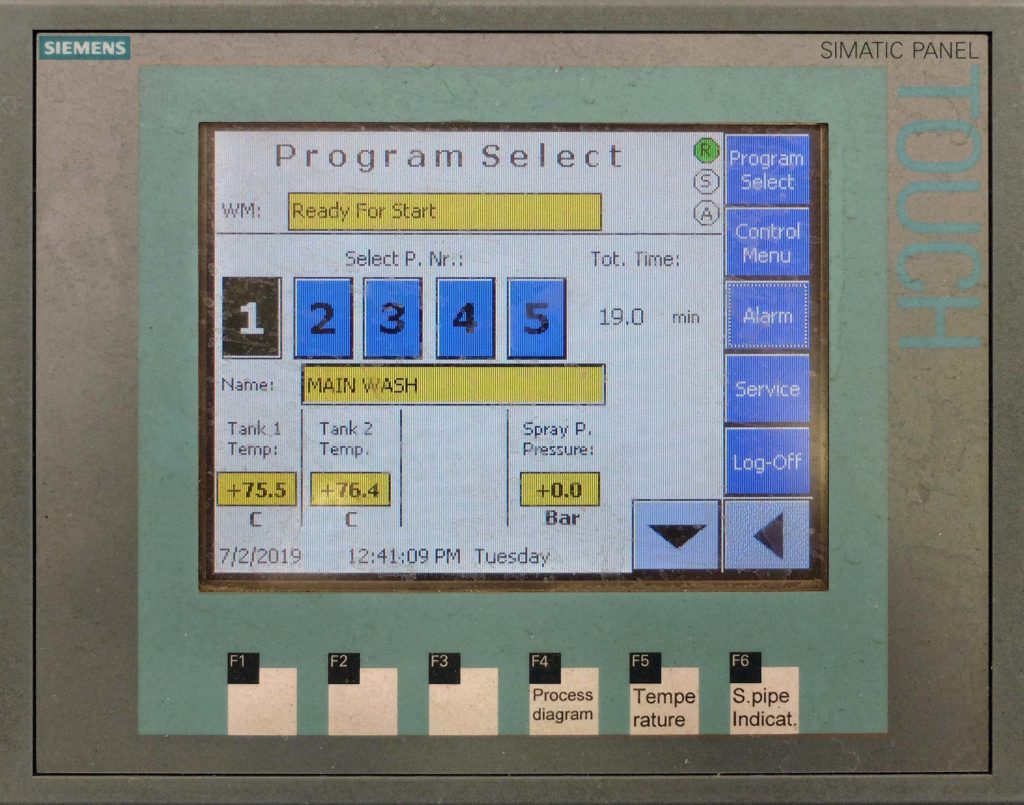

The AC-1.7-2 achieves this level of cleanliness in a fast cycle time due to efficient penetration of a mix of water and detergent at around 75°C via spray arms that are rotated around the load in the sealed, 1.4-metre-cube process chamber.

To minimise delay between the end of a cycle and loading of the next batch for cleaning, there is a shuttle arrangement at the front of the machine comprising two rail-mounted carriages, each carrying a table capable of supporting two tonnes.

While one batch is being processed, components are set up on the other table, which is ready to be pushed by the operator into the chamber as soon as the clean parts exit the machine via the automatic door.

Most components are washed in a single stage, but one category of parts – bearing housings – require two. They have to be rinsed, hence the need for a second water tank, so the process takes a little longer.

Lawrence Bradbury, Director of Engineering at Selwood, commented: “Even though we were impressed with the original Turbex machines, which had given two decades of good service, before replacing them we looked around at cleaning equipment on the market to see what was available.

“We took a batch of dirty castings to the Turbex technical centre in Alton, where their staff carried out a demonstration in a similar AC-1.7. The parts came out perfectly clean in a cycle time of just under 10 minutes, so we took the decision there and then to invest in this type of equipment.”

As part of the deal, Turbex also supplied a second washing machine, a CL-800, for which the two old aqueous rotating-drum machines were part exchanged. This equipment is used for processing smaller items that go into Selwood’s products, such as air pump components

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer