With a new multi-channel condition monitoring system (CMS) specifically designed for machine tools, Schaeffler is pursuing two objectives: first, condition monitoring and condition predictions for key components in machine tools using a single CMS, and second, the flexible integration of sensors from different manufacturers into the CMS.

With a new multi-channel condition monitoring system (CMS) specifically designed for machine tools, Schaeffler is pursuing two objectives: first, condition monitoring and condition predictions for key components in machine tools using a single CMS, and second, the flexible integration of sensors from different manufacturers into the CMS.

Condition monitoring systems for machine tools must fulfil complex requirements with regard to the available space and the number of drives components to be monitored.

Not only axes, feed drives and spindles, but also ancillary equipment such as hydraulic motors are important subsystems that can cause total failure of a machine tool.

In addition, manufacturers of subsystems and suppliers of ancillary equipment integrate their own measuring systems into machines.

A CMS for machine tools must therefore enable sensors from different manufacturers to operate with the machine.

Multi-channel CMS prototype for machine tools

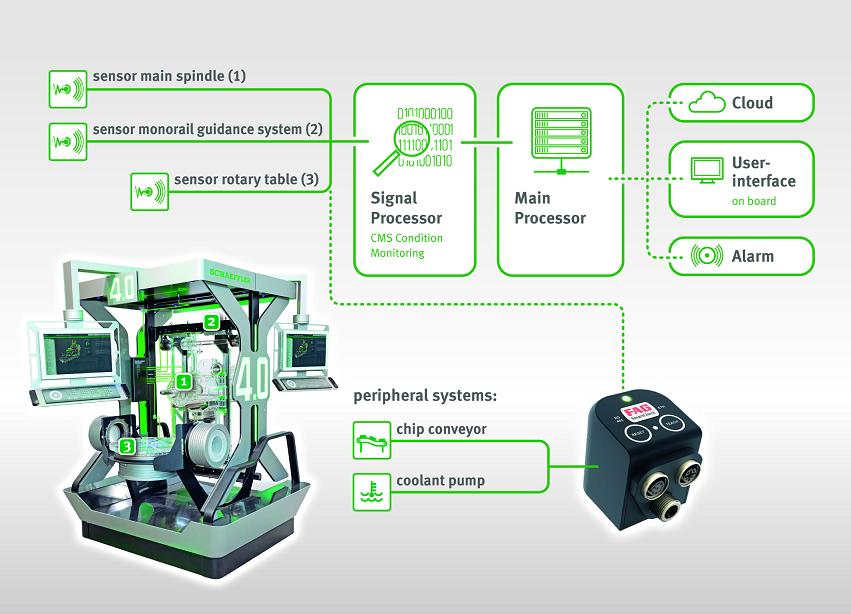

Schaeffler has presented a functional prototype of a multi-channel CMS for machine tools.

In-house systems and sensors such as piezoelectric vibration sensors can be connected to the CMS. Piezoelectric vibration, force and pressure sensors from other manufacturers can also be integrated into the CMS via an IEPE interface.

This offers a major advantage in that operators can use the sensors that are available and suitable for the individual measuring point and measurement task.

The current prototype has six measurement channels. The system is designed so that, for example, the electronic monitoring of the lubrication conditions in linear recirculating roller bearing and guideway assemblies can also be integrated in the future.

Software intelligence and cloud connection ported from other developments

The software for the prototype is very sophisticated, as most functions, algorithms and the optional connection to the Schaeffler Cloud from other projects can be ported with only minimal outlay.

Due to the connection to the Schaeffler Cloud, all digital services offered by Schaeffler for monitoring and detecting damage to rolling bearings are already available in the prototype CMS.

As a local solution, the multi-channel CMS facilitates the monitoring of FAG rolling bearings based on the integrated bearing catalogue, as well as bearings from other manufacturers (after entering specific bearing data).

A completely new development is the option to interpret vibration signals from ball screw drives. The beta version of the software module, which is currently in testing phase, will be available to customers shortly.

Simple to configure and operate with a web browser

Users can log on to the CMS and configure the system using a conventional web browser. The look and feel of the system and its operation are based on the FAG SmartCheck and its proven single-channel CMS.

The prototype for machine tools is intended primarily to provide pilot customers with the CMS functions in a development stage close to volume production status.

The design of the hardware is therefore of secondary importance. The prototype is currently being tested in initial pilot projects with various types of machine tools, including in-house production machines and selected partners.

At the same time, the system is also being implemented in Machine Tool 4.0 at Schaeffler’s manufacturing location in Höchstadt. This machining centre serves as a technology platform and development project for digitalised products in the machine tool sector.

Machine Tool 4.0 is used to develop and test the algorithms for the multi-channel CMS for monitoring and diagnosing the condition of rolling bearings and components in machine tools under real conditions.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer