Metals, plastics and rubber processing companies can now benefit from a comprehensive range of inline precision measurement and inspection systems from a single UK supplier.

Micro-Epsilon’s Systems Group specialises in the development, manufacture and installation of a wide range of non-contact, inline measurement and inspection systems for process monitoring and quality control applications.

These include specific measurement systems for metal, plastics and rubber, including thickness, length, speed and width measurement of strip, coil, film, sheet, tube and tyres.

Micro-Epsilon’s Systems Group has developed a range of robust, complete turnkey measurement systems that offer distinct technical advantages in terms of measurement accuracy, thermal stability and reliability.

This is backed up by installation, servicing, maintenance, technical support with guaranteed response times, retrofitting and upgrade services.

Chris Jones, Managing Director at Micro-Epsilon UK, comments: “We manufacture the sensor technology and all other critical parts including the electronics and software. The system mechanical design is also developed and assembled in-house, as this is critical to mechanical stability. All electrical hardware, including the PCs, is industrial-grade with solid-state memory. All these factors enable Micro-Epsilon to guarantee total system accuracy, reliability and to take full ownership of the complete system.”

“As well as offering our comprehensive range of inline, non-contact thickness and speed measurement systems for metals, we are providing a dedicated service to UK-based customers, including a 24/7 technical support hotline and a guaranteed on-site, rapid response service. We understand how critical it is for these companies to minimise production downtime and improve their product quality and so our engineers will be on call to assist the customer at all times. We can also provide customers with dial-in communications and remote diagnostics for measurement systems, which speed up our response times and enables our engineers to quickly rectify any issues that arise onsite,” adds Jones.

The measurement systems provide a variety of technical benefits including:

a. Automatic recalibration (C-frame and O-frame systems).

b. Turnkey systems that include sensors, software and mechanical frame (in C-frame or O-frame configurations).

c. Patented compensation frame available for all O-frame measurement systems. This ensures high precision measurements and a stable frame when temperatures fluctuate.

d. All O-frame and C-frame sensor technologies are non-contact, wear-free and do not use isotopes or X-rays.

Out-of-the-box thickness measurement

The latest addition to the Micro-Epsilon Systems range is thicknessSENSOR, an affordable and compact thickness measurement system for strip, plate and film targets.

The fully assembled system is immediately ready for use ‘out of the box’ and costs less than £10,000.

The system is designed to bridge the gap between customers’ own self-build solutions and the high cost, large investment thickness measurement systems that involve commissioning by the supplier’s own engineers.

The fully assembled thicknessSENSOR comprises of a stable C-frame onto which two laser triangulation sensors are mounted.

These sensors measure the thickness of strip, plate and film material such as plastics, metals, composites and fabrics.

The compact controller integrated into the frame calculates thickness values and outputs these via analogue or digital (Ethernet, USB) interfaces.

Due to its extremely compact design, thicknessSENSOR can be installed in confined spaces.

Using a calibration target, the two laser triangulation sensors can be calibrated at any time.

The thicknessSENSOR system is operated using an intuitive web interface.

Different configuration and set ups for specific measurement tasks can be selected using predefined settings, which means the system can be easily and quickly adapted to a range of different measurement applications.

Up to eight user-specific sensor settings can be stored and exported in the setup management. Video signal display, signal peak selection and freely adjustable signal averaging enable experienced users to optimise the system for specific measurement tasks.

A region of interest (ROI) function allows background signal noise to be filtered out.

The thicknessSENSOR system has a measuring range of 10mm, a measuring width of up to 200mm, at a measuring rate of up to 4kHz. Linearity (combined) is ±10µm and temperature stability of the system is <3µm/°C.

If the measurement performance of thicknessSENSOR is not sufficient for some customers, Micro-Epsilon’s Systems division can offer other non-contact thickness measurement systems with temperature-compensated frames that enable even higher precision, stable thickness measurements.

High performance C-frame systems

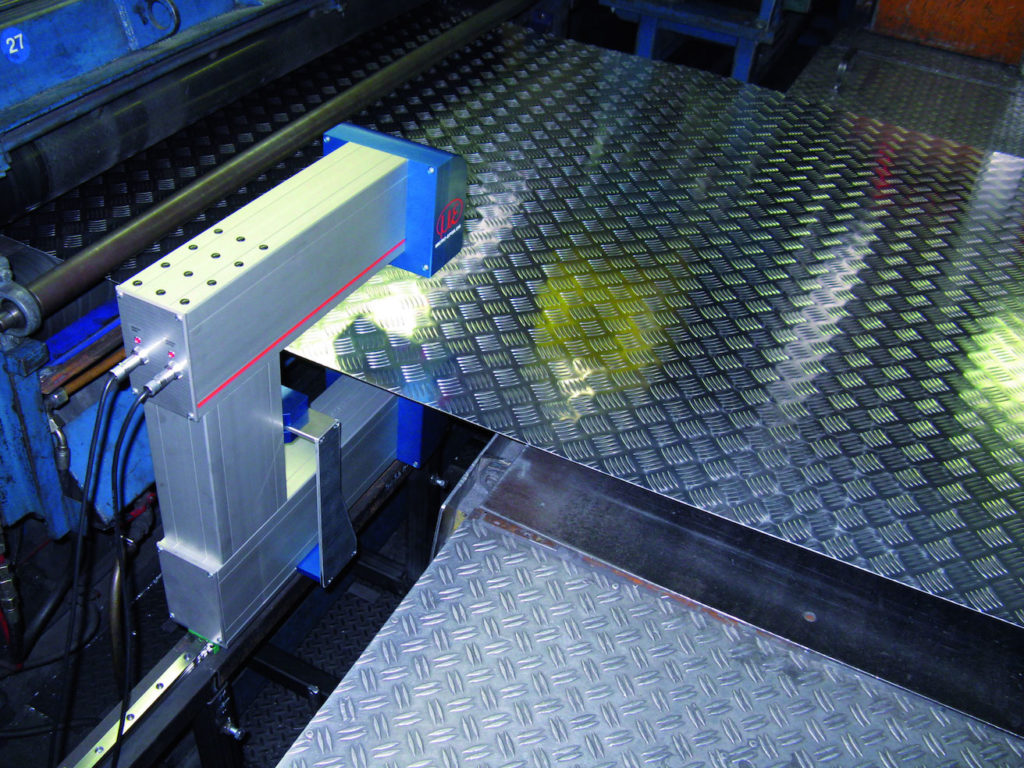

Micro-Epsilon UK‘s thicknessCONTROL family includes C-frame systems that are suitable for measuring the thickness, profile and width of metals, plastics and rubber materials.In the metal processing industry, C-frame systems are typically installed in hot and cold steel rolling mills, as well as slitting, coating, casting and cutting lines.

The systems are suitable for measuring flexible metal strip, coil, sheet and tube, including polished stainless steel and aluminium.

C-frame systems are also suitable for measuring the thickness, profile and width of plastic strip and sheet.

These systems are typically installed in extrusion lines for cast film or deep drawn film; blown film lines after collapsing; melting calendar lines; and extrusion lines for plastic profiles and plates.

In rubber processing, C-frame systems are typically installed in tyre production lines, extruders, rollerheads, calendar lines and inspection rooms, where they measure the thickness and profile of rubber strip and sheet.

Specific systems are also available from Micro-Epsilon for measuring tyres for passenger, truck and commercial vehicles, including systems for measuring the thickness profile of tyres, tyre treads, sidewalls and inner tube linings.

C-frame systems measure differentially and are modular in their design. Wherever they are installed, C-frame systems offer flexibility and high performance, providing reliable, high precision measurement results that create a basis for controlling the production process and product quality.

The C-frame can be used as a traversing thickness measurement system on linear axes in order to ensure full width measurements of the target.

The control and analysis software is developed in-house by Micro-Epsilon specifically to match the needs of the particular industry, providing all the required functions in order to continuously record and evaluate production quality.

This includes graphical user interfaces and the ability to store multiple product libraries.

Also, the software supports and displays Statistical Process Control (SPC) parameters and other ‘Process Capability’ analysis and reporting methods such as Six Sigma CPK and CPM. Various fieldbus interfaces are available, which enable integration to the customer’s production control systems.

Fully automatic calibration ensures that measurements are not affected by temperature, enabling the system to be installed as a fixed, inline measurement system in harsh production environments.

The C-frame system provides long-term measurement reliability at an affordable price. C-frame systems can be used to measure strip widths up to 1250mm and strip thickness from 10µm up to 50mm.

High performance O-frame systems for larger strip widths

For larger strip widths up to 4,000mm, Micro-Epsilon’s O-frame systems are ideal.

These systems measure differentially and incorporate many of the same features, functionality and software as C-frame systems, but also incorporate the desired measurement sensors (laser, optical, capacitive, etc) mounted to a mechanical linear guidance system that measures the complete thickness profile of the metal, plastic or rubber strip by traversing across the whole strip (or the thickness profile of each ring in a slitting line).

Micro-Epsilon’s FTS 8101 O-frame systems are able to measure plastic thicknesses from <100µm up to 10mm at accuracies of ±5µm. In rubber processing, O-frame systems from Micro-Epsilon are able to measure rubber thicknesses from 1mm up to 20mm at accuracies of ±5µm.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer