Fully or semi-automatic assembly of instrument panels in the automotive production process require the gripper tool to precisely position the panel in accordance with the vehicle chassis.

With each chassis potentially having a different variant or position, knowing where the tool is in relation to the chassis allows for smooth marriage of the two parts.

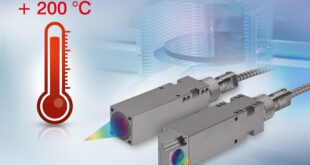

Due to their compact design, for easy installation on a robot or manipulator and their integrated 2D/3D profile measurement capabilities, non-contact laser profile sensors from Micro-Epsilon are used for this task.

During assembly, the gripper docks with the instrument panel module on the vehicle chassis.

When the module is successfully docked on both sides, laser profile scanners from Micro-Epsilon measure the current position of the module in the Y- and Z-axes against the vehicle coordinate system.

In order to determine the measurement values, reference points on the instrument panel skin are used, which are defined via specific intersections.

Subsequently, these measured values are compared with predefined set point values in order to determine whether the instrument panel has been positioned correctly.

When the values are calculated, an actuator is activated, which correctly aligns the instrument panel based on the reference points. In the next step, the instrument panel is fastened onto the car body.

As the laser scanners perform the measurement and positioning tasks, each instrument panel module can be individually adapted to the respective car body.

A laser profile scanner from Micro-Epsilon then evaluates the complete profile and transmits these measurement values via Ethernet to the control system. This enables the actuators to change the axis positions on the gripper in order to assemble the instrument panel in the ideal position in the car body.

After the module is fixed in place, the sensor then determines the installation position of the instrument panel, which serves as proof of quality for each vehicle.

For the entire process, including the fitting of the instrument panel, a cycle time of less than one minute is required.

Measuring independent of surface conditions, the laser profile sensors provide reliable measurement values regardless of whether bright or dark paints are used, different gloss levels, variable surface structures and in changing ambient light conditions.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer