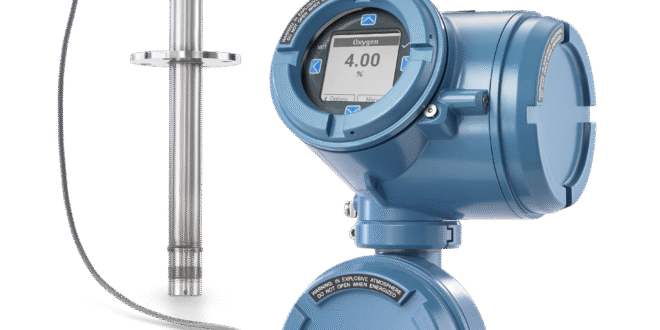

Emerson announces the new Rosemount CX2100 In Situ Oxygen Analyser, designed to provide critical information needed to optimise combustion processes and help manufacturers meet emissions standards, reduce energy costs, and increase safety. These types of analysers are widely used in a variety of industries, including power and utilities, chemical and petrochemical, pulp and paper, petroleum and refining, metals and mining, and others.

Existing oxygen analysers for combustion processes tend to be difficult to install, commission, and maintain — making it difficult to optimise combustion processes. By contrast, the CX2100 is simple to install, with a wide range of accessories for installation across different process conditions, including high temperature, high particulate, and high sulfur applications. The transmitter can be mounted up to 300 feet (91 metres) away from the probe to further simplify installation, especially important for personnel safety.

CX2100 commissioning is streamlined by the local operator interface’s guided setup and commissioning feature, with support for seven languages. The interface features capacitive touch buttons, comes with a wide variety of customisation options, and is housed in a rugged metal enclosure to protect its internal electronics. Guided setup can also be performed via a remote host, such as a control or asset management system.

Maintenance is made easy by the probe’s quick connect/disconnect feature, speeding replacement by eliminating the need for rewiring. Long service life is provided by ceramic or Hastelloy diffusers, which protect the probe from degradation in high temperature conditions, and these diffusers are field replaceable.

Autocalibration and autocalibration check features regularly measure analyser accuracy to help free technician time for higher value tasks, and to enhance safety by making sure the analyzer stays within its calibration limits. Safety is further improved by a flame safety interlock, which automatically turns off the probe’s heater when a flameout is detected.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer