To answer new environmental regulations and the need to reduce the chemical footprint of materials, Precision Sealing Systems (PSS) from Hutchinson Group is features LUBRITAPE-E, a transparent film applied to rubber parts, while while for low friction sealing pads for multi-way rotary valves. Designed as a direct replacement for PTFE solution, this coating delivers the same high-performance properties.

This offers Low-friction coefficient (Dynamic CoF Dry: 0.1 | Wet: 0.05); high resistance to abrasion; water-repellent surface; compatible with EPDM; temperature resistance from -50°C to +115°C

Featuring the new LUBRITAPE-E coating, the sealing pads offer: lower friction torque, for energy efficiency; optimal sealing solution; increased component service life; easy integration into automatic process

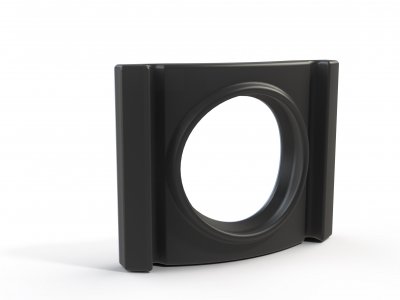

These sealing solutions are particularly suitable for thermal management modules and multi-way valves. They ensure leak-free operation while allowing smooth movement of internal parts, Sealing pads for multi-way valve even under high temperature and pressure conditions.

PSS develops rubber solutions to extend the service life of systems and improve vehicle performance.

As the automotive industry shifts toward new mobility solutions, especially electrification, our technical teams support manufacturers and OEMs by delivering customised solutions tailored to their evolving needs.

• Design expertise: engineering sealing solutions that address the mechanical, thermal, and chemical constraints specific to each application, ensuring optimal performance and reliability.

• Expertise across the full development cycle, including design, bench testing, validation, and industrialization of high-performance sealing solutions that comply with stringent industry standards.

• Advanced formulation capabilities: development of compounds engineered for harsh environments, ensuring chemical compatibility and long-term durability.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer