A lithium carbonate manufacturing plant in Asia has selected Sulzer to supply 18 pumps for its molten salts energy storage system. To support the rapidly growing electric vehicle market and maximise the sustainability of the end-product, the plant will be solely powered by renewable energy, with no grid connection. Therefore, the need for excellent reliability and high-quality manufacturing, led to the selection of Sulzer as the primary pump supplier.

Renewable energy sources, such as wind and solar, are recognised as offering variable supplies with time, both seasonally and day to day. One of the major challenges is to use a cost-effective storage solution that can enable energy generated during peak periods to be used when the sun has set, or wind speeds have dropped. One emerging method is the use of molten salts, which can be heated using solar energy and stored before being transferred to a heat exchanger to produce steam, which drives a turbine.

Round-the-clock energy

On the solar island, the arrangement for the plant includes both photovoltaic (PV) panels (35MW), electrochemical energy storage (20MW/40MWh), and a parabolic trough (PT) solar power plant including the molten salt storage system (47MW). The PV + PT systems supply energy during the day, with the parabolic troughs concentrating the sun’s energy on a pipe that contains a heat transfer fluid (HTF). This transfers the heat energy via heat exchanger to the molten salts, which are stored in a hot salt tank as well as being used to create steam.

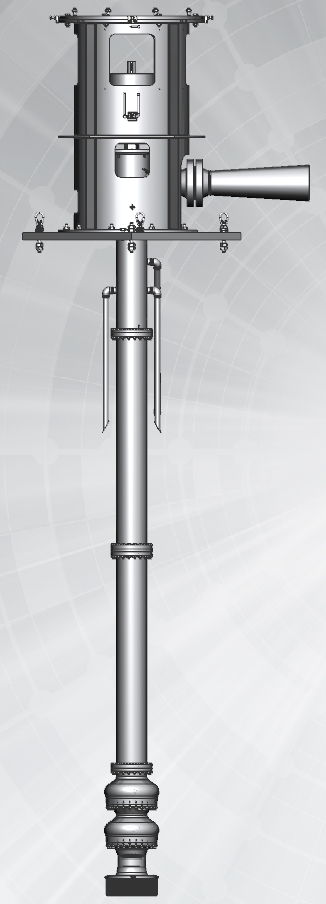

Sulzer will deliver all the major pumps on the solar island including six hot salt pumps and five cold salt pumps as well as four main HTF pumps and three auxiliary HTF pumps. All of these pumps will be manufactured in Sulzer’s Suzhou production facility, which offered a very competitive lead time for delivery.

Sulzer has a long history in designing and manufacturing molten salt pumps, which operate with media around 600°C (1,100°F). Sulzer’s pumping technology for this specialist application has been proven over many years, which was a major factor in winning the contract. Since the lithium carbonate plant will have no back-up energy supply, the solar installation must deliver optimum reliability.

One of the unusual aspects of this project is its elevation, 4,500m (14,700 feet) above sea level. This has a derating effect on electric motors, which are normally specified for use below 1,000m. The thinner air makes heat dissipation less efficient, requiring additional design considerations, such as a higher insulation class. In this case, the pump drive motors had to be specially configured for this project to account for the 40% derate caused by the altitude.

This installation is also using some of the energy generated by the PV panels to heat the molten salts, which is helping to prove how this energy storage system can facilitate PV-only generating setups.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer