The availability of machine data and the near real-time recording thereof, as well as storage and analysis, is decisive for …

Read More »Vibration monitoring and analysis helps prolong life of critical equipment

Schaeffler is providing route-based condition monitoring services to a cement works in Buxton, Derbyshire. As part of its annual service …

Read More »Requirements-based relubrication to prevent unplanned downtime of machine tools

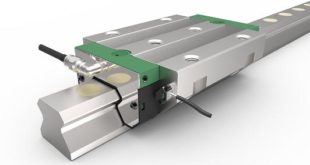

Statistically, defective rolling bearings and linear guidance systems are the most frequent causes of machine tool downtime. Insufficient lubrication or …

Read More »Condition analyses and predictions for machine tool components

With a new multi-channel condition monitoring system (CMS) specifically designed for machine tools, Schaeffler is pursuing two objectives: first, condition …

Read More »From wind farm to wheel

There is no single solution for the mobility of tomorrow. One reason is that in the development of environmentally friendly …

Read More » Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer