There is no single solution for the mobility of tomorrow.

One reason is that in the development of environmentally friendly propulsion systems, the diverse demands made on transporting people and goods in the various regions of the world must be taken into account.

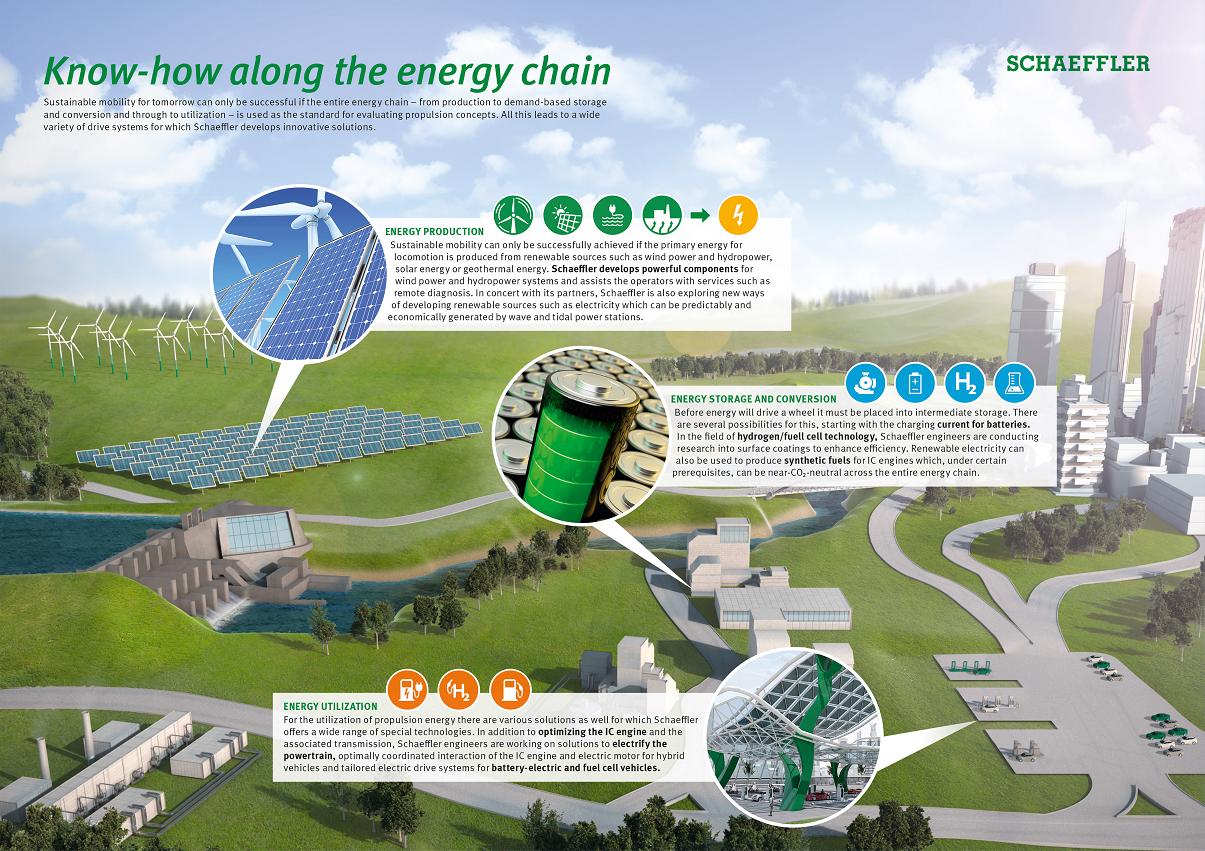

Another reason is that looking at local vehicle emissions is not enough. Sustainable mobility can only be successful when propulsion concepts are measured against the entire energy chain.

Furthermore, bringing the energy into the vehicle requires it to be stored based on demand. All these considerations result in a wide variety of propulsion systems for which Schaeffler is developing appropriate solutions.

The electric vehicle travels around the city emitting hardly any noise. The battery provides a range of more than 500 kilometres.

On the road, the electric vehicle produces zero emissions. The battery is charged quickly using a power cable or by means of induction, while the vehicle is parked or even while it’s moving.

For many people, this is the best scenario for mobility of the future. The mobility issue will have been resolved once the challenges posed by electric vehicles – sufficient range, fast charging and affordable purchase cost – have been resolved.

In Schaeffler’s view, though, this is just one element in the mobility of tomorrow.

“Electric vehicles can essentially meet people’s needs for personal mobility in urban areas,” says Prof Peter Gutzmer, Schaeffler’s Chief Technology Officer. “However, it’s not only the propulsion concept of a vehicle that is critical. Equally important is the way in which the energy needed for propulsion is generated and stored. Otherwise there is a risk that CO2 emissions are merely shifted from one place to another.”

Experts refer to ‘well-to-wheel’ when taking the entire energy chain into account. It’s a method that enables the amount of CO2 emissions being produced within the entire event chain of locomotion to be investigated – from the production and storage of energy through to its conversion into kinetic energy.

According to calculations made by Schaeffler, an electric vehicle still emits up to 65% of the CO2 amount of a comparable vehicle with a petrol (gasoline) engine, based on the current electricity mix within the European Union.

By contrast, if the batteries of an electric vehicle are charged with 100% electricity generated by renewable sources, its CO2 emissions will drop to just three per cent of those of a conventional vehicle.

This clearly shows that sustainable mobility can only be achieved if the primary energy for locomotion comes from renewable sources such as wind power, solar power, hydropower or geothermal energy.

For the manufacturers of wind turbines, for example, Schaeffler develops high performance, low-friction components and bearings for the drivetrain and supports operators with services enabling remote diagnostics and predictive maintenance of these systems.

In order to develop additional energy sources, Schaeffler, together with its partners, is engaged in research pursuing completely new approaches – such as exploring the question of how sustainable and, above all, effectively predictable electricity can be generated by wave and tidal power systems.

Before electrical energy can find its way into a passenger car, it must be stored. Again, there is not a single approach to storage either.

Electricity cannot be used only to charge a battery, but also to produce hydrogen by means of electrolysis.

Subsequently, in the vehicle, this hydrogen can be reconverted into electricity, for example, to power an electric car. This is why Schaeffler’s engineers also conduct research on how a fuel cell can be operated with maximum efficiency, for instance, by coating “bipolar plates” that are at the core of any fuel cell.

A major disadvantage of hydrogen technology is the current lack of infrastructure. Germany, for example, has only a few dozen hydrogen filling stations at present and their number is still very low around the world too. However, a country-wide network of filling stations is the key prerequisite for a successful rollout of this propulsion technology.

Electricity from renewable sources can also be used to produce synthetic natural gas or synthetic liquid fuel.

For example, to produce substitute diesel fuel based on “green electricity” synthesis gases are produced using electrical energy and subsequently synthesised in several processing stages.

Under certain prerequisites, the resulting designer fuels can be near-CO2-neutral across the entire energy chain and made available by the existing filling station network to power the internal combustion engines of vehicles.

“The internal combustion engine will continue to be an important element in transporting people and goods,” Gutzmer emphasises. “This not only refers to passenger cars but, above all, to commercial vehicles, ships and aircraft, for which no serious battery-electric alternative will be available in the foreseeable future.”

A look at the entire energy chain shows that there is no single solution for mobility of tomorrow. Therefore, Schaeffler is developing a wide range of systems and components for a diverse set of requirements.

In addition to the further optimisation of the conventional internal combustion engine and the transmission systems that go with this, Schaeffler’s engineers are working on solutions to electrify the powertrain, optimally coordinated interaction of the internal combustion engine and the electric motor for hybrid vehicles, and on tailor-made, efficient electric drive systems for electric vehicles.

“The mobility world of tomorrow will be as diverse as the people that want to be mobile,” says Gutzmer.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer