Travelling from A to B at record pace in the Hyperloop – that’s the vision of Tesla’s CEO Elon Musk, who is pushing the development of this innovative transportation technology.

But this high speed mode of transportation requires precision sensors to take over important measurement tasks.

Compact infrared temperature sensors from Micro-Epsilon check the surface temperature of drive wheels, battery voltage, current, engine temperature, engine speed, ambient pressure and pressure in pneumatic systems.

The Hyperloop resembles the principle of a pneumatic dispatch (tube) system. Electrically driven transport capsules are conveyed on air cushions using solar energy through a tube in partial vacuum.

Elon Musk has been pursuing his idea of fast locomotion. He claims that the Hyperloop enables travel speeds up to 1,500km – significantly faster and cheaper than by train.

In June 2015, the SpaceX Hyperloop Pod Competition was organised with the aim of accelerating the development of Hyperloop.

Students at the Technical University of Munich participated in this first international competition. The teams had to design transport capsules known as ‘pods’.

Of more than 700 teams who applied for this competition, just 30 were invited in January 2017 to test their capsules in the 1.2km long pipe in California.

The WARR Hyperloop Team of the Technical University of Munich was selected out of three teams to send its capsule through the tube. Visionary Elon Musk observed the capsule’s travel in person.

Only the capsule designed by the Munich students got to the finish and won the main prize for the fastest Hyperloop pod developed by more than 32 students.

In summer 2017, the students also won the second Hyperloop contest in Los Angeles. They achieved top speeds of 324 km/h (>200 mph).

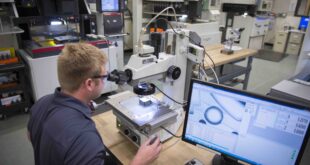

The high speed transportation capsule is, among other things, equipped with thermoMETER CSmicro miniature infrared temperature sensors supplied by Micro-Epsilon.

Their task is to monitor the surface temperature of the polyurethane-coated drive wheel and 10 coated running wheels. The drive wheel has a radius of 80mm and achieves maximum rotational speeds of 12,000 rpm. The running wheels have a radius of 25mm and keep the vehicle on the rail.

The surface temperature must be inspected during the capsule’s travel and also in the internal test bench in order to ensure durability of the wheels and to control their wear. The temperature of the polyurethane coating on the wheels should not exceed 120°C.

Knowing these values also enables the evaluation of limits and permanent load in order to make improvements if required.

In order to be able to precisely determine the surface temperature of the wheels, the thermoMETER CSmicro temperature sensor is installed about 75mm above the surface of the drive wheel.

A circular, high resolution measurement spot with a diameter of 7mm is positioned at the centre of the wheel, which enables the exact determination of the temperature.

The challenge of this measurement task is the high rotational speeds under difficult thermal conditions in a vacuum. This high rotational speed makes contact measurements impossible. Therefore, non-contact sensors must be used that can withstand the harsh vacuum conditions and that provide precise, reliable measurements.

As a vacuum does not allow thermal conduction, sensors with a low degree of heat loss must be used. This means that the components cannot be cooled using ambient air.

The thermoMETER CSmicro fulfils all requirements of the measurement task. With its compact dimensions, this miniature sensor can be easily installed in restricted installation spaces. It has a diameter of 14mm, a length of 28mm and is equipped with an M12 fine thread.

The controller is integrated in the cable. Furthermore, the sensor loses only a little heat due to its low power consumption of 9mA. This means that hardly any heat emanates into the vacuum.

Due to the compact electronics being remotely mounted in the sensor output cable, 0.5mm from the sensor head, the controller is not exposed to the hot environment surrounding the target.

The sensor can be used in ambient temperatures up to 120°C without cooling, while the measuring range extends from -40°C to +1,030°C. The silicon-coated lens is extremely robust.

The sensor comes with a scalable analogue output and a simultaneous alarm output providing analogue and digital connections. Digital programming for additional applications is possible.

Martin Riedl, a member of the WARR Hyperloop Team at the Technical University of Munich, is very satisfied with the sensor solution from Micro-Epsilon: “The thermoMETER CSmicro is a compact unit that enables us to measure the precise surface temperature. Analogue and digital connections give us great flexibility.”

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer