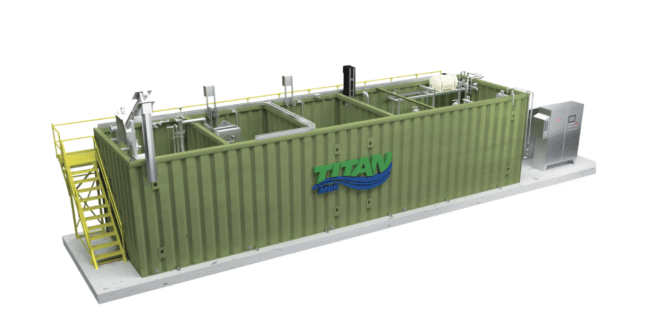

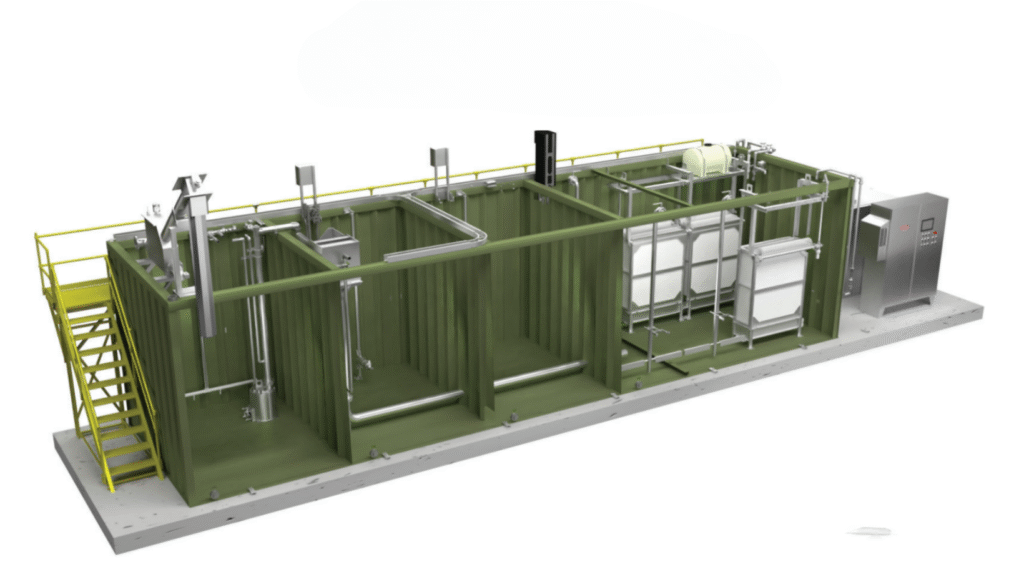

Smith & Loveless‘ TITAN MBR is a factory-built membrane bioreactor system that delivers high-efficiency wastewater treatment with streamlined operation and maintenance.

Engineered to provide the simplest O&M of any MBR system, the TITAN MBR features compact, factoory-built and tested models that reduce field assembly, shorten installation time, and enable faster startup.

Each TITAN MBR system is built in the United States and comes equipped with epoxy and polyurethane-coated V-Crimp tankage, flat-plate submerged membrane modules, stainless steel internal components, prewired instrumentation, and QUICKSMART touchscreen PLC controls. The system offers robust design, smart automation, and cloud-based monitoring through RemoteView services, helping operators monitor and control system functions from anywhere.

With energy-efficient performance and no permeate pumps, the TITAN MBR reduces energy usage by up to 30%. The flat-plate PVDF+PET membranes are automatically cleaned in place typically twice per year with no need for removal. This in-place process lowers chemical use, minimizes downtime, and simplifies maintenance. The membranes also resist breakage and perform well even with stringy solids, offering longer life and lower fouling rates than other membrane types.

The system achieves superior effluent quality, with typical values of <3mg/L BOD, <1mg/L TSS, <0.2NTU turbidity, and <0.05mg/L total phosphorus with optional process selections. The TITAN MBR meets California Title 22 standards for water reuse and includes automation features such as decanting, chemical cleaning, and nutrient removal via optional anoxic zones. Recycle control and aeration are also managed automatically for optimised performance.

Designed for flows from 5,000 gallons per day to 0.1MGD, the TITAN MBR is available with enhanced features including OBEX fine screening, separate blowers for airlifts and the MBR zone, odor control packages, stainless steel tankage, and skid-mounted chemical cleaning systems. Smart Wire Management minimises field wiring with factory-installed cable trays and instrumentation.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer