Leading systems integrator, Boulting Technology has launched a new risk management plan, providing plant managers with an all-encompassing maintenance solution.

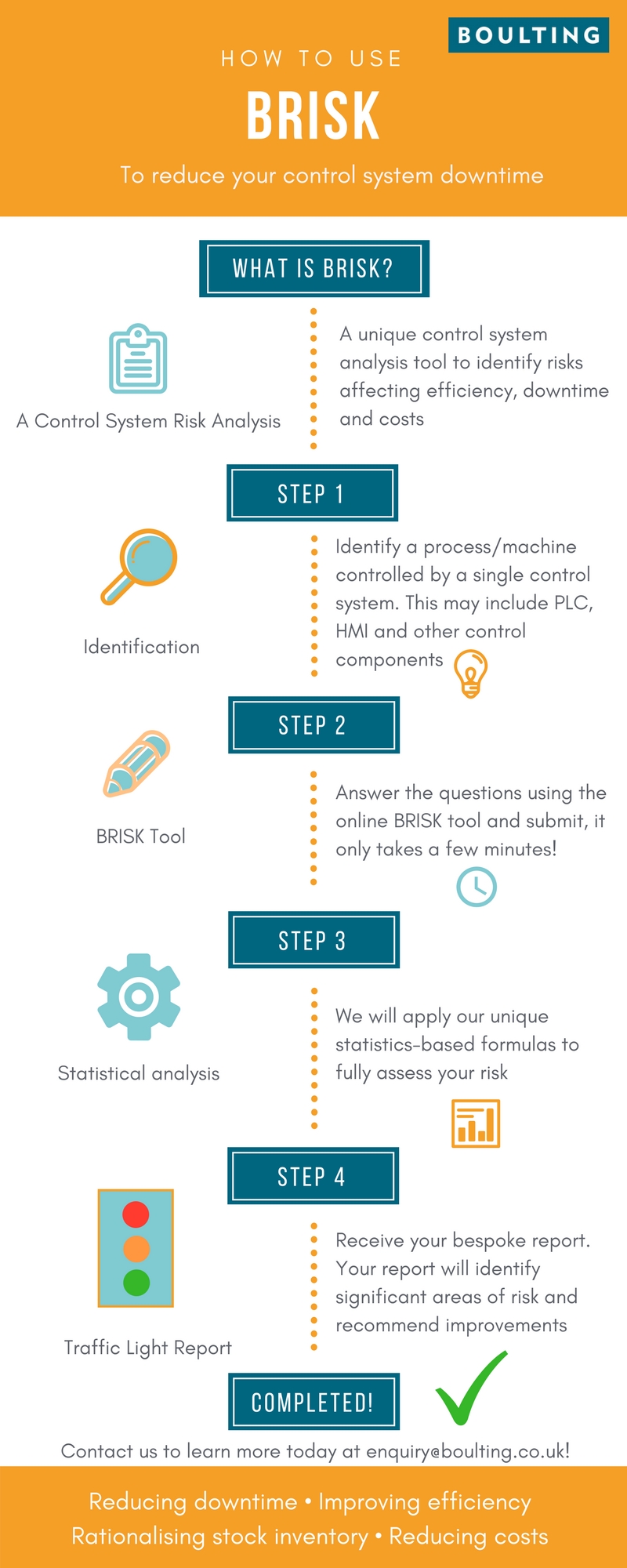

The new programme consists of a comprehensive survey that assess control systems across a facility. A survey, conducted by Boulting’s engineers, provide plant managers with a report detailing the potential risks posed by equipment, such as control system failure, critical obsolescence and other scenarios that could cause unplanned downtime.

Unplanned downtime can not only cost a business thousands of pounds a day, it can also prove detrimental to its reputation, negatively impacting relationships with clients.

Boulting Technology’s new risk management assessment allows plant managers to spot problems before they happen and put solutions in place, reducing the potential for unplanned downtime.

The initial online survey assesses areas such as obsolete parts, equipment life cycle, and efficiency. The corresponding report uses a traffic light system to make recommendations.

The multi stage recommendations, which are based on clients’ key parameters, provide a hierarchy of risk. This helps to characterise and focus on the high risk critical systems in the first instance, enabling the plant manager to implement an appropriate and cost-effective action plan.

The no obligation risk management programme is the newest addition to Boulting Technology’s portfolio of service and support offerings, which also includes 24-7 support for system breakdowns.

“By proactively managing risk, plant managers can plan maintenance schedulee around the equipment they currently have and so avoid costly breakdown and downtime,” explained James Davey, service manager at Boulting Technology.

“Control system maintenance is particularly important as these systems are often integral to the whole facility. PLC and SCADA systems are the heartbeat of a plant, so if they fail the whole plant may be vulnerable,” Davey continued.

“Initial feedback from our clients has been overwhelmingly positive, particularly from the low margin high volume industries, for which unplanned downtime can be particularly devastating.”

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer