Where is a digital twin actually used? Dr. Christian Scheifele explains the potential of a solution that significantly simplifies the commissioning of machines and plants – and therefore saves time and costs

In its simplest form, a digital twin is a virtual model of a process, product or service. This pairing of the physical and digital worlds enables better analysis of data, design and development of new opportunities and planning for the future using simulation models.

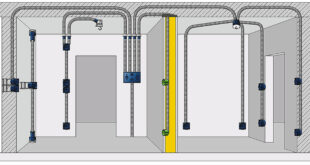

KEB Automation and ISG, a provider of digital software solutions for engineering, have been working together for some time. Among other things, the co-operation has proven itself with the ISG Kernel as a software solution for CNC machines. Now, KEB and ISG are going one step further and are also working together on the digital twin. With ISG-virtuos, ISG provides simulation technology that enables virtual commissioning with the help of a digital twin.

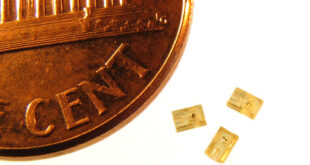

Building on this, the so-called ‘TwinStore’ is an online store or exchange platform on which component manufacturers such as KEB Automation can store their digital twins and offer these to machine and plant manufacturers for virtual commissioning. This eliminates lengthy modelling times for the user when it comes to setting up a digital twin. The pre-designed models of individual components, which KEB makes available for download in the TwinStore, can be easily integrated by the customer in ISG-virtuos and then pulled into the individual model. In a short time, plant and machine builders can now create a digital twin for their application, which consists of KEB components.

Users benefit from this process in several ways. As the complete control software can be tested in advance on the digital twin of the machine or plant with ISG-virtuos, the real commissioning can be optimally prepared and possible errors detected and eliminated in advance. In this way, it is possible to reduce the time required for commissioning by up to 90 per cent and work in an extremely resource-friendly way, as well as minimise risks as far as possible, particularly in complex projects.

Dr. Christian Scheifele is Managing Director of ISG Steuerungstechnik.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer