An environmental solutions company that was committed to implementing circular economy principles in managing waste to preserve finite natural resources, faced a challenge in maintaining its hydrogen production process due to low natural gas supply.

To overcome this issue, Burckhardt Compression supplied a quick, cost-effective solution involving expansion technology, enabling the gas supply to be restored to the required level. This ensured that the hydrogen production process could continue smoothly while meeting sustainability goals.

As part of its commitment to sustainable waste management practices, an environmental solutions company produces hydrogen through steam methane reforming, which is used in various applications such as fuel cell vehicles, power generation, and industrial processes, contributing to the reduction of greenhouse gas emissions.

Originally, the company received natural gas at a supply pressure of 16 bar (232psi). However, it was later advised that the pressure would be gradually reduced to 8bar (116psi) and then to 4bar (58psi). To maintain hydrogen production, a solution was needed to maintain the natural gas supply at the original pressure of 16bar. The customer’s on-site engineering team had the task of sourcing two compressors quickly, and on a limited budget, which could handle the gradual change in process gas pressure and ensure that the hydrogen production process remained unaffected.

After evaluating their options, the engineering team identified an ideal solution available from Burckhardt Compression.

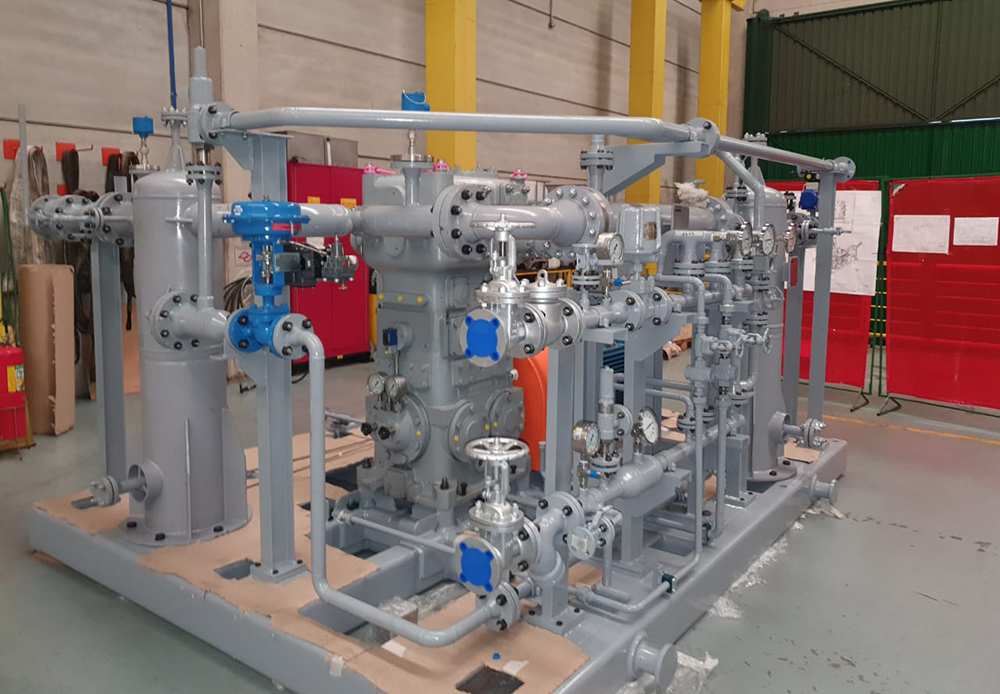

Burckhardt Compression supplied and installed two second-hand Laby 2K90-2E gas compressors, which had never been used before, allowing for a faster delivery time of only five months, much shorter than that offered by other companies.

The two Laby compressors were delivered from stock in Switzerland as bare shaft compressors. Site installation and commissioning were carried out by experts from Burckhardt Compression Brazil with support from the engineering team in Switzerland.

Burckhardt Compression delivered a fit-for-purpose, future-proof turnkey solution with a long operational life, maintaining the gas at its original pressure, ensuring sustainable long-term customer investment. The project was also delivered on budget, which allowed it to achieve its goals without incurring more costs.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer