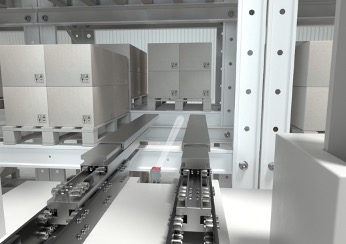

The new IPS 400i from Leuze electronic is the smallest camera-based positioning sensor on the market for double-depth compartment fine positioning. It helps high-bay storage devices to quickly and easily find the right rack.

With the new camera-based IPS 400i positioning sensor for high-bay storage devices, Leuze electronic – the expert for sensor solutions for intralogistics – is expanding its IPS range of products with a new model for optical compartment fine positioning.

About a year ago, Leuze electronic introduced the IPS 200i, the smallest camera-based positioning sensor for single-depth, which is used for single depth pallet high racks and small-part container storage.

The new IPS400i is just as compact as its sibling, the IPS 200i, and thus requires little space on the high-bay storage device – however, it detects round holes or reflectors not only in single-depth, but also double-depth bars and thus determines the position deviation relative to the target position in the X and Y directions. This makes the new camera-based IPS 400i positioning sensor particularly suited for use in double-depth pallet high-bay warehouses.

A model with integrated heating for use in refrigerated warehouses down to -30 °C is also available.

Both variants – IPS 200i and IPS 400i – offer the user simple and fast commissioning and operation.

The sensors are put into operation using a web-based configuration tool with a user-controlled installation assistant (wizard). Printed configuration codes are read in without a PC via ‘Code Generator’, which means that configuration adjustments can be made directly on the high-bay storage device.

An alignment system consisting of four feedback LEDs further facilitates the commissioning process. Due to its powerful, ambient-light-independent IR LED lighting, fault-free use in warehouse technology is possible with just one single device for a working range of up to 2400mm.

With the integrated TCP/IP interface and PROFINET RT, the IPS 400i can be directly integrated into the network environment and enables quick, location-independent diagnostics.

Condition monitoring and predictive maintenance take place using a quality score that detects deterioration in the reading performance of the sensor at an early stage. This minimises downtime and increases the availability and cost-effectiveness of the systems.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer