Customised precision couplings are vital for builders of specialist equipment.

Precise machines must operate with high efficiency and reliability within a compact footprint.

Not only must a coupling be of an optimal design to promote uptime, but also sympathetic to overall device packaging.

An off-the-shelf coupling will not offer the specialisation required, so a customised component is often the best option. These customised precision couplings may be required for the machine prototyping process or for low to medium volume production runs.

Product development deadlines or manufacturing schedules must be met, which means precision couplings must be delivered swiftly.

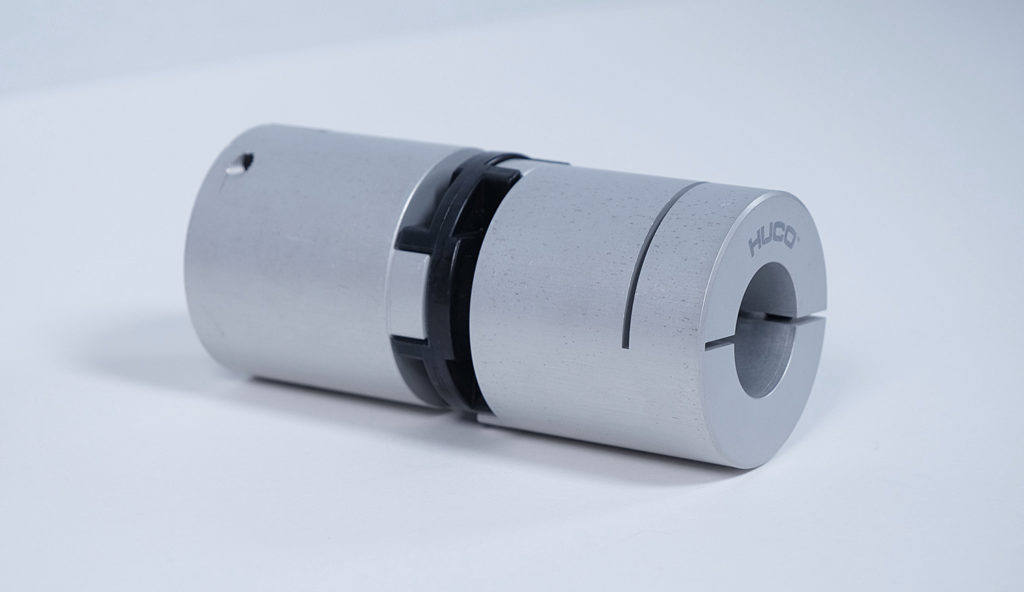

Huco, a brand of Altra Industrial Motion Corp., is a regular supplier of customised couplings and cardan shafts to the precision automation, motion transfer, medical and laboratory sectors.

Typical applications include pick & place machines, assembly machines, transfer machines, printing equipment, sorting, medical devices and testing equipment.

Offering an in-house design and manufacturing capability, the business has built a reputation for being able to provide customised couplings with a wide range of specifications on short lead times. Huco can complete the design process in days, with average sized orders manufactured and delivered in a couple of weeks.

Choice for specifiers is wide. Huco is famous for its flagship Oldham coupling, which eliminates backlash and protects against shock loading via a central disc mechanism.

Beam couplings are another speciality, with both more flexible single-beam and more rigid multi-beam variants available. Alternatively, Bellows couplings offer high torsional rigidity for precise position control. Huco is able to design and deliver custom couplings in all of these styles to suit shafts from <1 up to 65 millimetres diameter.

Where Huco’s customisation service shines is its machining of both Oldham and Beam couplings onto custom shafts as a complete assembly.

A large machining capability makes this possible, offering customers specialised and unusual configurations without greatly extending lead times.

Conversely, Huco can also design and manufacture couplings to fit pre-existing shafts, such as Bellows couplings that can be simply attached. Ultimately, Huco offers flexibility to ensure a tailored solution to fit a specific machine.

Small or large orders can be easily catered for; allowing end users to specify single couplings or replacement shafts, an engineer to source a small number for prototyping, or a machine builder to specify a larger order to support an entire production run.

In any eventuality, all will receive a quality solution produced specifically to their requirements on a reduced lead time.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer