Every train is fitted with alternators to generate electrical power and each one has an automatic voltage regulator (AVR) card that ensures the correct voltage is produced.

However, in some cases, reliability has become an issue for these cards, which has led Sulzer to develop a service to repair or redesign and manufacture replacement AVR cards.

The function of an AVR is to maintain the output voltage of a generator at a constant value that is independent of the generator loading or temperature.

There are numerous alternator designs used on trains developed by individual manufacturers, and each one uses a different design.

In the event of a fault, AVRs are quite easy to replace as a service item and rail maintenance depots hold spares as a matter of course.

However, like-for-like replacement doesn’t get to the root of the problem or improve performance.

A pro-active approach is required where the component is analysed and re-designed to ensure better reliability.

Over the years, there have been numerous manufacturers of alternators supplying the rail industry and this has led to a myriad of different components being used on the national rolling stock fleet.

Some of them have since fallen by the wayside, leaving operators little choice but to replace complete alternator assemblies when only the AVR is at fault.

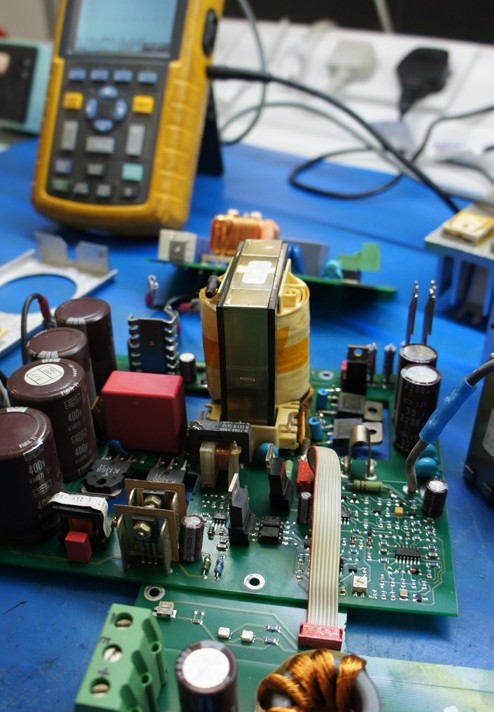

To address this issue, part of Sulzer’s rail engineering team has set up a program to assess, redesign and manufacture replacement AVRs that will offer improved reliability.

The aim is to reduce lost availability of rolling stock and to minimize the costs associated with AVR repairs.

Paul Keely, Technical Manager Sulzer Rail Competence Center, explains: “We can assess an existing design, take account of current reliability issues and use this information to design and manufacture a replacement. Using a thorough design and test procedure, an improved design can be created and manufactured to overcome issues with support and supply from OEMs.”

Working closely with rail operators, the design team aims to identify any issues or concerns with the existing AVR designs and create long-lasting solutions that promote reliability.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer