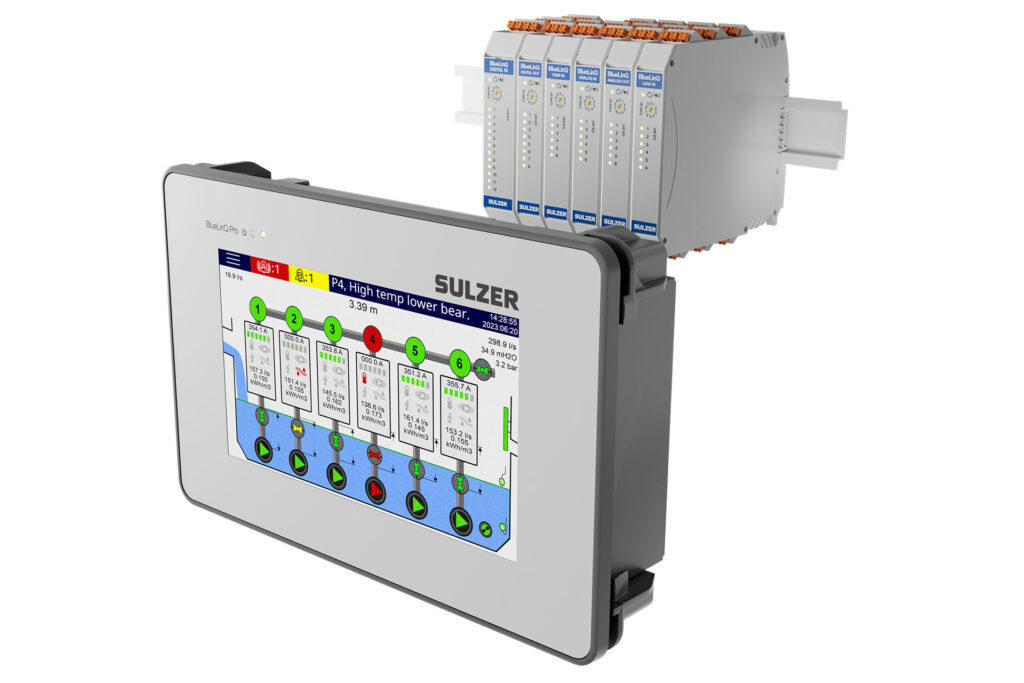

Network pumping stations invariably encounter challenging conditions, and operators can face an uphill struggle to maintain reliability and low operating costs. BlueLinQ Pro, the latest addition to the Sulzer pump controller lineup, uses an intuitive, quick set-up wizard for simplified configuration and uses experience-designed presets to solve complex operating scenarios. Operators can interact seamlessly via the 7-in touchscreen and use the integrated variable frequency drive (VFD) control to maximise pump efficiency and reduce energy costs. The new BlueLinQ Pro offers excellent scalability and is capable of controlling up to six assets including pumps, mixers and valves for the most effective operations.

Plug-and-play performance

The Sulzer BlueLinQ Pro offers advanced control features and a setup wizard that improve pump availability and reduce energy consumption – all within a small footprint that makes retrofitting easy. Built-in best efficiency point (BEP) and proportional integral derivative (PID) control logic functionality ensures that all pumps in the station operate as close to peak efficiency as possible. This reduces running costs and minimises stress on the mechanical components.

Smart control functionality provides multiple features that optimise pump operations and minimise the need for interventions from the maintenance team. The ability to calculate in and outflows, measure the speed of level changes and vary pump start and stop points ensures each pumping station operates to its full potential. This includes the addition of mixers and valves, which can also be included in the control logic delivered by the BlueLinQ Pro.

Simple module installation and configuration optimises any retrofit by using multiple preset features to enhance performance. Round-the-clock remote monitoring and detailed analytics provide enhanced insights that support maintenance projects and minimise unnecessary call-outs.

Simplifying complex tasks

With so many very similar pumping stations in each network, the variety of controllers across sites can add unnecessary complexity for operators. The inherent flexibility of the BlueLinQ controller makes it ideal for many locations. Once the first station has been configured, all the settings can be easily transferred to others using the SD memory card facility, minimizing commissioning time.

To further enhance the benefits of the BlueLinQ Pro, modern communications protocols offer excellent connectivity and remote access possibilities to maximise the effectiveness of operators and technicians. Centralised monitoring and programing ensure valuable staff and resources are only dispatched when absolutely necessary.

The features of this pump controller from Sulzer can support strategies to reduce operating costs, maximise reliability and optimise the productivity of the whole network.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer