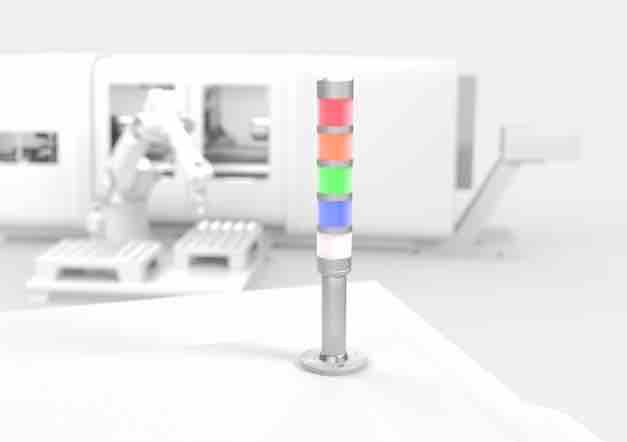

Leuze introduces new tower lights in robust aluminium housing onto the market. The TL 305 series offers bright and homogeneous illumination and an optional IO-Link interface.

Tower lights are indispensable in machine and system construction as, well as in intralogistics. They make states, faults, and ongoing processes clearly visible from a distance.

The new Leuze tower lights of the TL 305 series can do all of this extremely reliably. They light up brightly, uniformly, and fully. This enables optimum signalling – whether at the machine, on the conveyor belt, or for access control. The compact towers are available pre-configured with three, four, or five segments. The new range of tower lights includes the TL 305 models with a predefined colour assignment, as well as the TL 305-IOL models with an IO-Link interface. The IO-Link variants allow different operating modes and provide an extensive selection of colors. On request, the tower lights are also available with an additional acoustic signaller.

Quick and easy implementation

System operators benefit from the immediate usability of the tower lights. The M30 thread and M12 connectors make them easy to install. Matching accessories simplify installation. All models of the series are characterised by a high-quality and robust design. The aluminium housing allows the tower lights to be used even in demanding industrial environments.

Flexible configuration

The IO-Link version TL 305-IOL with its different operating modes offers maximum flexibility. Segment mode enables the segments to be actuated individually via IO-Link. This allows colour, intensity, and lighting sequences to be configured individually. Level mode is used to visualise fill levels. If fast commissioning is required, users can actuate eight predetermined or user-defined configurations via the three external trigger inputs even without an IO-Link connection.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer