Proprietary SCADA provided by automation vendors can be challenging to use, restrictive in choice and expensive. Alternatively, independent SCADA software, controls and comms architectures demand significant expertise and resources in system design and integration. So, is there a middle way in SCADA implementation? Carl Nash reports

A supervisory control and data acquisition (SCADA) control system provided by the big automation vendors is commonplace. The main reason for their popularity is the perception of security and low risk. These brands are established and likely to maintain their support and ongoing development. They also create ease of selection and hardware integration – providing the vendor’s own equipment is used.

Yet the lock-in presents its own challenges. The most obvious drawback is the restriction on the choice of software and controls.

From a development perspective, if not already conversant with the software environment, the user likely faces significant time and cost, especially where some vendors don’t enjoy a reputation of ease of use.

Lack of choice over software and hardware can also limit capabilities, not only for central control but peripheral control as well.

Vendor-supplied SCADA can mean that wider automation components and communications have to follow suit, or else require additional time and cost integrating optimum component choice from various manufacturers.

From the procurement perspective, vendor-supplied SCADA is the most expensive option. This cost restraint applies to initial purchase, and once locked in, additional licences can further inflate the expense.

Alternatively, SCADA software, control components and comms architecture can be selected independently. The clear benefit of the widest choice means a programming environment and language which may already be familiar, or preferable from an ease of use perspective.

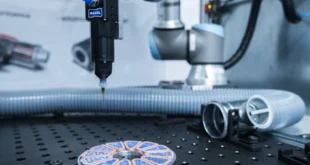

Creating a SCADA system independently also means access to best of breed products and a choice of communications protocol. At the same time, choice affords lower cost – at least over initial system set-up.

While maximising flexibility, the fully independent SCADA approach demands significant expertise and time in design. This issue can be exacerbated the wider the automation system grows over time.

A challenge is cost in resources for set-up, and also time to market. Depending on your choice of brands, your system may also be in a more or less precarious position concerning ongoing updates and support.

It is possible however to benefit from the ready integration of vendor-supplied SCADA, with the flexibility of an independent system. This middle way demands an automation partner that can provide support throughout, from system design to field support.

The advantage of working with a SCADA specialist that can advise and provide hardware and software as a package means ease and speed of project delivery; and enables optimum system integration.

It’s advantageous if your SCADA partner can offer a tailored system, where bespoke requirements can be supported for specific application needs. Also ensure that the hardware and software will be supported on an ongoing basis to futureproof your investment.

To enjoy best of breed hardware, it’s important the SCADA software is independent, providing flexibility in initial choice as well as future scalability should your needs expand.

The SCADA software platform will ideally offer an all in one development environment for managing HMI/PLC, visualisation, data history and analysis, with the primary advantage of reduced development time. It’s also crucial that the platform is easy to use and flexible to changing applications.

The controller should also be scalable to accommodate changing needs, therefore hardware with a robust and powerful processor (Mid-range Intel for example) is advantageous at the outset.

Hardware should also be backed up by local technical support, with a rapid response when required. In our opinion, these combined benefits can also be achieved at a price far more competitive than that from one of the proprietary automation vendors.

Image Caption: Creating a SCADA system independently also means access to best of breed products and a choice of communications protocol. Image: Products4Automation

Carl Nash is Technical Director at Products4Automation.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer