Chris Lloyd explains the advantages of 3D printing for industrial enclosure development

There was a time when prototypes for bespoke industrial enclosures were expensive and took weeks to produce.

Thanks to advances in 3D printing, today’s prototypes are not only faster and less expensive to develop, but the increased possibility to make design tweaks creates a better final product.

3D printing was developed in the 1980s to speed up manufacturing development through the creation of rapid prototypes. Since then, 3D printing (also known as additive manufacturing) has progressed to the extent that it has now taken over part, or even all, of the manufacturing processes for some operations.

However, for the majority of applications, prototype development remains the most focussed use of the technology, driven by the increasing need for faster time to market.

For the development of new or bespoke industrial enclosures, 3D printing has significantly reduced prototype development time.

For the OEM, the faster the time to make, test and approve a prototype, the faster their time to market and the quicker they can see a return on their investment. This is an ever-increasing trend, especially for industries where profitability is squeezed and the cost of labour and expertise is high. For some projects urgency is critical, and a prototype might be needed in a matter of days. This is what 3D printing can provide.

The capability of 3D manufacture itself means that a prototype can be created that is extremely similar to the final product, both aesthetically and based on the desired properties.

Using conventional manufacturing techniques, the cost of developing a prototype is significantly higher, which can sometimes make new product developments unviable.

Alternatively, 3D prototype production is faster and as the printer is usually segregated from the main manufacturing process, it doesn’t impact normal manufacturing flow in the way that a small run of prototypes would if they were constructed on the main production line.

Since taking on its first 3D print capability in 2008, Spelsberg has harnessed the technology to develop more advanced bespoke enclosure projects, doing so in much quicker time. Spelsberg can either work from supplied design files or collaborate with the customer to create the design. Print manufacturing is then achieved via the Polyjet process.

Using a digital drawing as the basis for production, the Polyjet printer applies extremely thin layers of plastic until the design is created to the given dimensions. Liquid polymers are jetted onto the printer bed and UV light is used to cure the plastic, hardening it. It’s also possible to design in features such as impact or heat resistance and in addition the prototype can be adhered, printed or metalised with aluminium.

This means that the enclosure prototype can undergo functional testing, such as IK impact resistance, and can also be assembled with components and electrical distribution to ensure that it meets the application requirements.

As the polyjet printing process takes place by applying very fine layers, it creates an extremely smooth surface, even for curves or joints, which means a highly realistic final product finish. Another benefit of the polyjet process is the versatility of the types of plastics which can be used, with diverse choice over colour type to aspects such as rigidity. If required, multiple material types can also be blended.

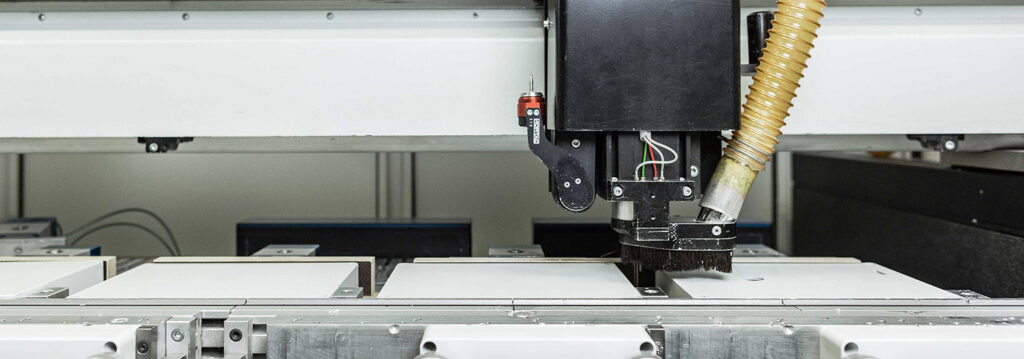

As a result of the flexibility of the development process, design changes can be rapidly implemented with new prototypes manufactured quickly. 3D printing can also be combined with additional customisation techniques such as CNC machining, all of which can be planned and implemented at Spelsberg UK’s Telford site. Crucially, this means not only a tailored design of enclosure, but a fast service which can be delivered in a matter of days.

Chris Lloyd is Managing Director at Spelsberg UK.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer