The control cabinet is the heart of every electrical system. Precise and efficient cabinet design forms the basis of successful engineering, right up until the finished cabinet is commissioned. The seamless integration of all processes along with a tightly synchronised production chain is enabled by tailor-made electrical engineering software from WSCAD.

At first glance, control cabinets for buildings or industrial systems are nondescript grey metal boxes. However, they conceal intricate switching systems for the supply of energy to equipment in places as varied as production lines, shopping malls or hospitals. Depending on the design and equipment of buildings and systems, cabinet engineers often need to manage complex electrical schematics, cabinet assembly, manufacturing, and installation on site.

Access all project data

A holistic electrical engineering solution needs to cover the entire cabinet design process while ensuring integration with associated building systems and equipment.

Leading electrical engineering software manufacturer, WSCAD, is focused on the consistent digitalisation of control and switchgear engineering. The current generation of WSCAD ELECTRIX contains a complete tool set for the design, construction and manufacture of electrical control and supply units. It features an advanced Design Engine (editor) and integration with standard DXF/DWG CAD formats as well as the ability to interface with the most important component manufacturers and higher-level enterprise software. This electrical engineering package includes a comprehensive parts database and access to the wscaduniverse.com online database with its fast search filters. Equally attractive to engineers and service technicians is support for modern technologies such as augmented reality, multi-threading, and automation functions for practically any task, with data easily transferable to the workshop and the production team.

Getting the right order

The arrival of an order starts the process for the design team. Imagine the specification calls for a fast, customised control cabinet design. Its basis is a schematic diagram with cabinet design drawings.

Within the WSCAD software portfolio, these are handled by two specialised modules: Electrical Engineering (EE) and Cabinet Engineering (CE). When it comes to the electrical design of building services, the Building Automation (BA) module for the plant layout and control diagrams as well as the Electrical Installation (EI) module for installation planning enable efficient project delivery. Each tool contains a range of templates which consist of standardised symbols, part master data, macros, and any recorded data points, such as terminal schematics, automatically generated material and connection lists as well as standard-compliant documentation.

Fast cabinet production

All WSCAD modules are fully inter-compatible. Every new input or change to the electrical and cable design, once confirmed, automatically updates all other project views including specifications and connection attributes.

For instance, switchgear manufacturer NW Niemann calculates its quotes based on initial design data. As soon as an order is received, the relevant schematic diagrams are produced to fit the subsequent cabinet design and manufacture.

“Everything runs on the WSCAD platform. All project-relevant employees are kept up to date on every planning stage and can act accordingly. The seamless exchange of data avoids duplication of work and saves huge amounts of time,” says Holger Pawel, Managing Director of NW Niemann in Vechta, Lower Saxony.

WSCAD users do not have to wade through product catalogues when choosing components and modules. The electrical designer connects directly with the wscaduniverse.com online database via WSCAD software and can access a dedicated search engine. Once the desired device manufacturer has been selected, the designer clicks on the corresponding components with the required attributes. Major manufacturers such as Wago or Phoenix Contact also provide direct access to their product configurators and online shops. This data is seamlessly imported into the WSCAD database and is simply dragged into the cabinet design with the mouse.

The same applies for routing cable connections and assembling wires or harnesses. The designer defines cross sections, colour codes, lengths, and properties of cable connections in WSCAD software. Wire lengths and cable trunking capacities are calculated with just a click. With the auto-routing function, the software automatically finds the optimal routes for all connections and calculates the wire lengths. There are no more label printing errors, as the descriptions for wire and terminal strips, as well as the other electrical components and QR codes, come directly from the original project data.

Design in 2D, test in 3D

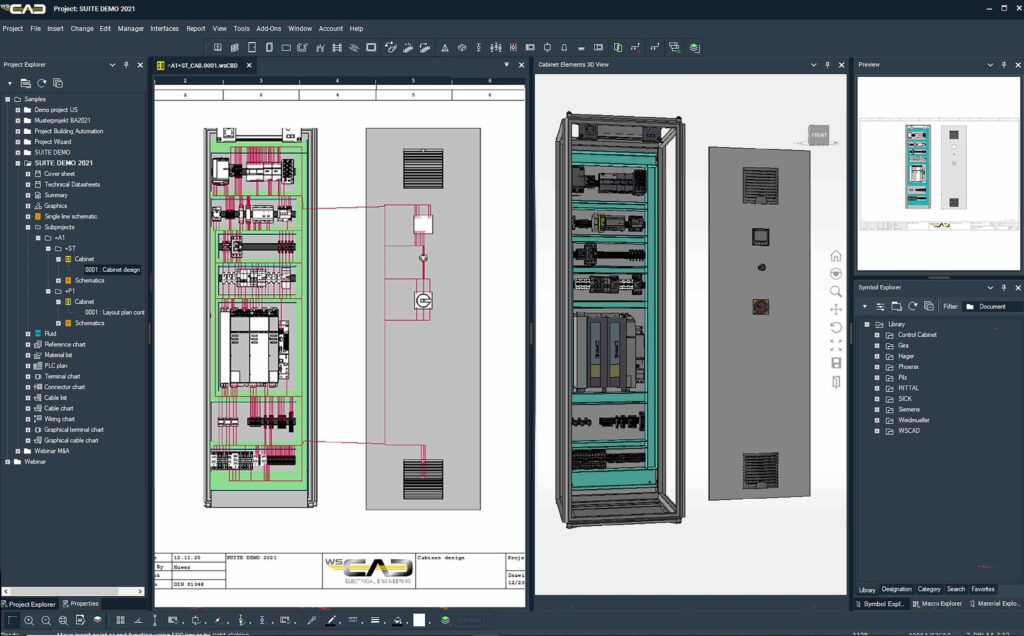

While many designers still prefer to design in 2D, plausibility tests of cabinet layouts can be carried out using photorealistic 3D representations. The 3D view provides a better spatial overview and shows the actual component dimensions, accurate to a tenth of a millimetre. This is especially important for collision-free placement of components. The same applies for the dimensioning of mounting plates, cabinet doors, cable trunking and rails.

The final benefit is mobile access to barcoding of a cabinet and its individual components – ideal for maintenance and service technicians. The Cabinet Augmented Reality (AR) app contained in the electrical engineering software from WSCAD scans the labels and links them with the cabinet’s corresponding WSCAD project. Depending on requirement, the mobile device will provide access to relevant component or module information such as reference ID, function text, part number, electrical schematics, and the manufacturer’s original data sheets.

In all aspects of cabinet design, WSCAD electrical engineering software provides the tools for users to deliver quickly consistent quality. Furthermore, its extensive, intuitive features provide easy access to relevant specifications and information throughout the cabinet lifecycle.

Image 1: Cabinet engineering with WSCAD is quick and easy. The continuous digitalisation of processes unlocks increased automation in engineering and production backed by consistent quality

Image 2: 2D and 3D construction, automatic routing, filling level display of the cable ducts and the generation of data to produce wire sets and cabinet housings on NC machines are included at no extra charge

Image 3: The included WSCAD Cabinet AR App identifies components and retrieves information from the Cloud. Notes on components can be added within the Cabinet AR App using the comment function

Image 4: The app-supported wiring of control cabinets is much faster and more convenient than the traditional paper lists and circuit diagrams

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer