Global battery manufacturer Ultralife Corporation has released a whitepaper outlining the core considerations for choosing lithium thionyl chloride cells or battery packs for industrial and commercial devices.

The whitepaper, which is HERE, offers a checklist for design engineers and original equipment manufacturers (OEMs) specifying batteries for electronic device applications, based on various performance, physical size and price-point factors.

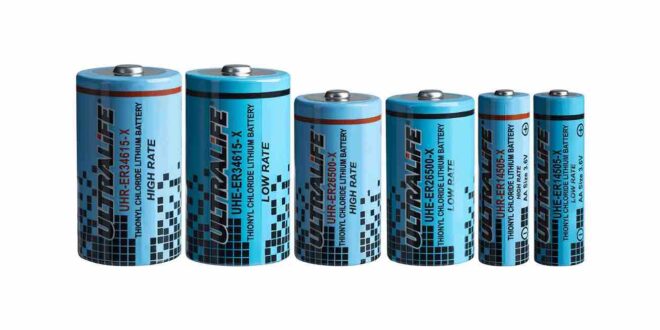

Lithium thionyl chloride (LI/SOCI2) cells and battery packs are often referred to as ER batteries. The LI/SOCI2 chemistry is commonly used in commercial and industrial applications that require reliable primary battery power with an extended storage and operating life.

However, despite being commonly used across multiple markets, all ER cells are unique and can offer differing physical and performance characteristics.

In the whitepaper, Ultralife highlights several of the factors that design engineers should consider and the specific details that can influence battery or cell performance. This includes power characteristics such as electrical current rate requirements, battery capacity and voltage, as well as physical and environmental factors including operating temperature range. The paper also outlines how to calculate the number of cells needed for an application, allowing design engineers to accurately estimate the footprint of a battery pack.

“Lithium thionyl chloride has long been one of the highest performing chemistries for portable electronic devices or compact applications such as sensors, utility metering or asset tracking tags,” explained Robert Brown, marketing executive at Ultralife Corporation. “As such, ER batteries continue to be staples of modern commercial and industrial applications.

“There is no one size fits all approach to specifying batteries, particularly not ER cells. For example, when we consider voltage, a standard ER cell has an open circuit voltage of 3.65V. These cells can be loaded into a cell holder in a series string to offer higher voltages in consumer devices, but this linear architecture does not ensure the continuity necessary for critical industrial applications. This is just one of the decisions an engineer or OEM must make when specifying cells and batteries.

“Another is off-the-shelf availability. Lead time availability of quality cells has been an issue in the Li/SOCl2 market in recent years but Ultralife can offer off-the-shelf availability of low quantities or short lead times for volume quantities of production units (location dependent).”

Ultralife Corporation’s ER Generation X cells feature an energy density of more than 400 Whr/kg, as well as boasting up to 30% greater capacity performance than competitors (average across temperatures). Building on Ultralife’s extensive experience in mission-critical industries, the batteries also have an extended operating temperature of -55 to +85˚C and are available as spiral or bobbin versions in a range of standard sizes.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer