When looking at micron-level tolerances, there are now not just traditional technologies but also new micro Additive Manufacturing technologies that can provide an efficient route to market. When shortlisting suppliers, these technological capabilities need to be assessed, and so does the way that a supplier works with its customers and the culture that exists that drives innovation and creativity. Aaron Johnson reports

When you need to produce precision micro plastic parts, you will necessarily begin to approach specialist moulding companies, and most likely the ones that brand themselves as micro moulders. As the drive towards miniaturisation continues apace, more and more companies are initiating conversations with suppliers that seemingly hold the keys to their product success. The route to market is typically through the use of a micro moulding partner. This is because even if the cost of investing in the technologies necessary to make precision plastic parts was not deemed prohibitive, the knowledge and experience necessary to operate them in a world where single micron tolerances are the norm are very rare indeed.

So the success of a product development program now becomes a lesson in supplier selection not technology selection. And in the area of micro moulding, a supplier is so much more than just a moulding company. It is a company with in-depth design experience, a material expert, a tooling expert, a validation expert, and of course a production and assembly expert.

It’s all about perspective

So where do you begin when selecting your microplastic product development partner?

It may seem logical to start by asking whether your prospective partner makes microplastics parts. Obviously, in some way or another, the answer to this question needs to be ‘yes’. But in a very real way, a microplastic part manufacturer is so much more than a company that sells small plastic parts, and instead should be seen as a company that sells Design for Micro Molding (DfMM). The plastic parts are the end result, but the engine for success is ensuring that the design of the part is optimised, tooling is optimised, it can be made efficiently, it can be measured effectively, and if necessary it can be automatically assembled.

As such, your chosen supplier must be vertically integrated, with all stages of the product development process being considered in early customer/supplier collaborative design meetings, and teams of experienced experts being able to influence the ultimate success of a project.

Let’s get vertical

Fundamental to the success of the production of microplastic parts is tolerance attainment. As such, product development is all about risk mitigation, ensuring that tolerance ‘drift’ is managed and kept within the parameters that ensure the integrity of end-use parts and components.

So saying, the focus is on control, and to fully control the development of a product from initial design to final automated assembly all expertise and technology used must be under one roof. A fundamental question from the get-go is to ask whether your chosen supply partner can offer in-house design expertise and material assistance, micro tooling fabrication, micro moulding and micro additive manufacturing (micro AM) technologies, validation, and automated assembly.

Some suppliers say ‘yes’ when asked if these capabilities reside in-house, but in fact, they outsource various parts of the product development process. There are risks associated with outsourcing. At its most basic, there is a loss of control. True vertical integration exhibits the ability to be able to support and control a product development program from end-to-end, as it removes the headaches of dealing with multiple vendors, and streamlines the entire product development process. Visit your shortlisted product development partner, and see for yourself just what is actually ‘in-house’. The key is to see evidence for yourself and take nothing for granted.

Size can be everything

OK, so you’ve looked under the bonnet, and you have seen evidence of true vertical integration for yourself. So far so good. But what about the size of the operation you are dealing with?

You see, capabilities are only one part of the equation. Just as important are scalability and sustainability. Your chosen supply partner may have ticked all the vertical integration boxes, but in terms of production, is the infrastructure big enough to support your volume requirements over an extended period of time? You see, some customers require millions and millions of parts with a continuity of supply running over years. Put quite simply, without the space to accommodate this scale of supply and the associated manufacturing cells, then your chosen partner may be found wanting.

Also, to sustain supply over many years, you need to be persuaded of the robustness of the supply partner that you are dealing with. How long have they been in business, how deep are their pockets, can they survive recessionary (or pandemic-associated) downturns?

A good barometer here is how long your chosen supply partner has been in business as a micro moulder or precision plastic part producer. Some suppliers may boast a long pedigree, but ask how long they have been producing real parts, as some businesses have a foundation in precision engineering that goes back years, but are relatively new when it comes to actually producing micro and precision plastic parts. Also, take a look at turnover. You will see from this which companies are operating at scale and which are relative minnows.

Only with decades of microplastic part production under its belt will a supplier have the experience and strength and breadth of knowledge to tackle the most exacting of customer applications. Yours does not want to be the first project of its kind that your supplier deals with. Ask for evidence of the longevity of manufacturing, and also look for evidence that your supplier has been around the block numerous times with projects such as yours.

Let’s work this out together

We have described micro plastic part suppliers as your ‘partners’ in product development, and this is a word used advisedly. The relationship you have with your chosen supplier should be a true product development partnership, and this demands a healthy client-supplier relationship.

This is your project. As such, you want to remain in touch, involved, and influencing outcomes, not just handing over control to your chosen micro plastic part expert who holds all the secret sauce. Yes, you are working with your chosen partner as they have the expertise, capabilities, scalability, and sustainability to see your project through. But you must insist upon — and see evidence of — collaboration and transparency in client-supplier dealings.

Your chosen micro moulder should have a solutions-oriented focus, and a demonstrable reputation in the various industry sectors for high quality, timely, and cost-effective results.

More about capabilities

We placed an emphasis on vertical integration earlier in this article, and this is all about the capabilities that your chosen supplier has in-house. Let’s delve a little more closely into the capabilities that will back up the ability to scale up and sustain the mass manufacture of microplastic parts.

Design and material expertise are pretty fundamental to success. As mentioned earlier, true micro plastics part producers are selling DfMM expertise, not plastic parts, and your chosen micro moulding supplier should be able to intervene to optimise manufacturing outcomes. Without this ability, and without the ability to be able to advise on the best approach for any given application, there is an increased chance that time and money will be lost due to the need for design re-iterations, and even more seriously the need to adapt hard tooling. Your micro moulding partner should be able to enhance the innovative nature of your microplastic parts by intelligent design input in the early stages of product development.

The ability to fabricate micro tooling in-house is also critical. Some see micro tooling as the key enabling technology for successful micro moulding success, so be careful to see evidence of experience and the routine attainment of micron tolerances. Be aware, however, that extensive experience in micro tooling without a similar level of experience in micro moulding can be an issue.

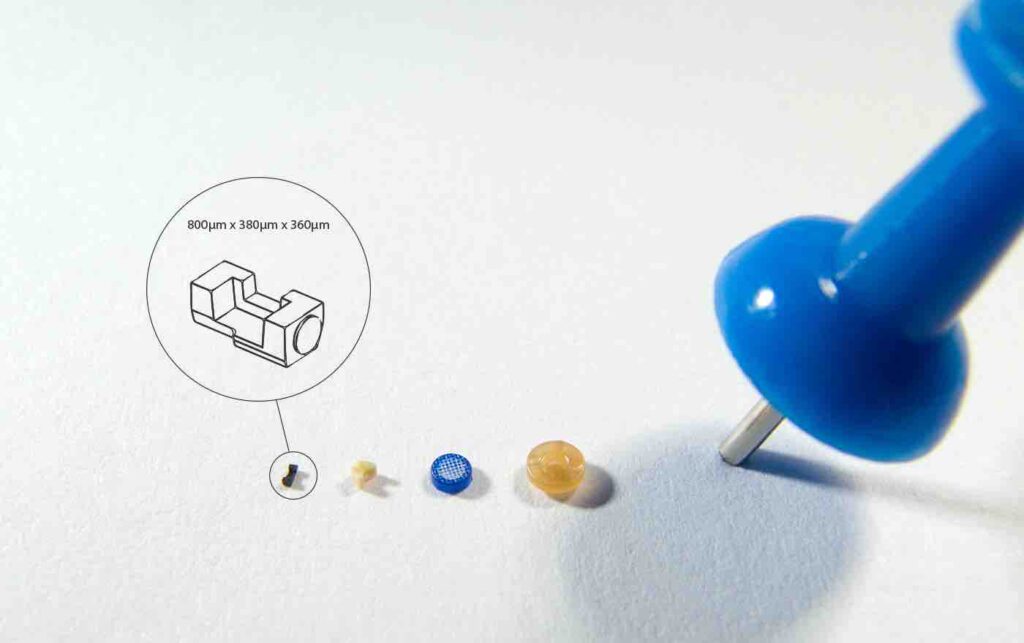

Micro moulding is an obvious capability to examine, but look beyond the obvious evidence of micro moulding machines, and seek evidence of a consistent and long track record of micron tolerance attainment. Ask how many and what micro moulding machines your supplier has in-house.

Then there is the new kid on the block, micro AM. Micro AM can cater for customers requiring low- to medium-sized runs, as the same economies of scale do not exist when using AM as compared to traditional moulding technologies. Micro parts with geometric complexity either impossible or prohibitively expensive using the micro moulding process can also be made. However, it is in the area of direct rapid soft tooling (DRST) that there are huge future opportunities.

The accuracy of today’s micro AM technologies and the robustness of the materials used mean that the technology can produce DRSTs that can be used on traditional moulding machines. This unlocks new business possibilities for customers as it means that they no longer need to rely on long lead time and expensive traditionally manufactured mould tools for prototype runs all the way through to mass manufacture. Micro AM stimulates the business case for a process chain that includes DRST, with the possibility of dramatically shorter lead times from file to injected part and at costs reduced from thousands of dollars to tens. This will be a game-changer for some projects and should be on your shopping list of supplier capabilities.

Your chosen partner must also be able to validate the accuracy of parts made. This requires a suite of top-end metrology solutions, both in the lab and also in-process. Without the ability to measure often geometrically complex and tiny parts with absolute precision, it will be impossible to prove the attainment of design intent, and this will render parts made useless.

Finally, make sure that your micro moulding partner has the capacity and ability to provide customised automated assembly in-house. Your chosen partner must be able to demonstrate an understanding of — and experience in — the art and science of micro-assembly, with a focus on minimising the level of handling, as at each stage tolerances can be affected.

Summary

The key to success in supplier selection is to see the evidence. Claims are easily made, but when you seek evidence of experience, longevity, vertical integration, capability, scalability, and sustainability, it is a little harder to gild the lily. Don’t be shy about asking questions, and where possible, visit your shortlisted suppliers. You are about to embark on a project that may cost hundreds of thousands of dollars, so scrutiny is essential and should be welcomed by your product development partner.

Aaron Johnson is VP of Marketing and Customer Strategy, Accumold.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer