Automated control of water systems, whether in swimming pools, washrooms, or drinking water supplies, needs reliable equipment that minimises water hammer and the effects of dezincification.

Bürkert’s Type 6213 solenoid valve achieves this and can be specified to meet even the most demanding applications. It is available through the company’s e-commerce site and local valve suppliers.

Plumbers and maintenance staff often come across solenoid valves that control water flow, usually when the issues have been raised with the application, such as leaking valves or water hammer noise in the pipework.

Finding suitable replacements or spare parts has now become easier and quicker, thanks to Bürkert’s wide range of specifications that can be applied to the Type 6213.

Any water system operating with mains supplies, can be at risk from dezincification. This is a process where chlorine attacks soft brass components and is especially prevalent when the water is stationary for extended periods of time.

While the main fluidic parts are made from hardened brass, some of the smallest, more intricate components are very often made from softer brass.

For situations such as toilet cistern systems located in schools which are unused during holiday periods or swimming pool top-up systems that are dormant during the winter, dezincification can be a challenge. In these applications, it is better to use materials in the construction of the valves that are better-suited to the conditions. This can include the use of hardened brass components throughout or the use of stainless steel in place of the soft brass.

The challenge of water hammer, however, can affect any water system that has a valve installed in it. If the valve is closed too quickly the sudden increase in pressure causes a shockwave to travel along the pipework.

The magnitude of the pressure increase can also cause problems for other pieces of equipment that are installed in the system.

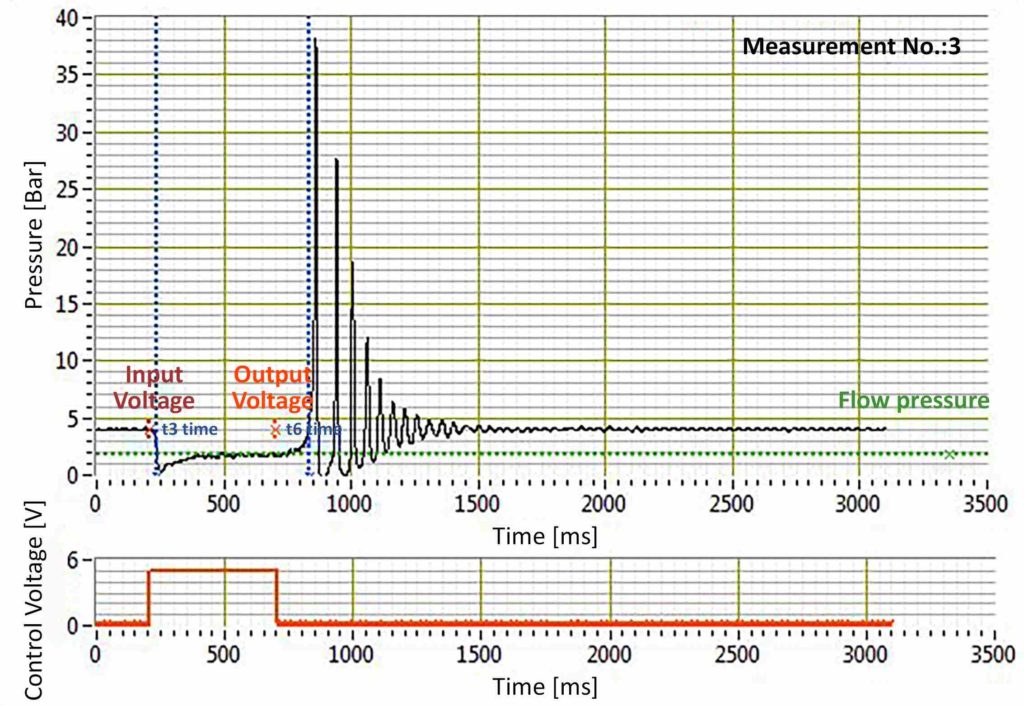

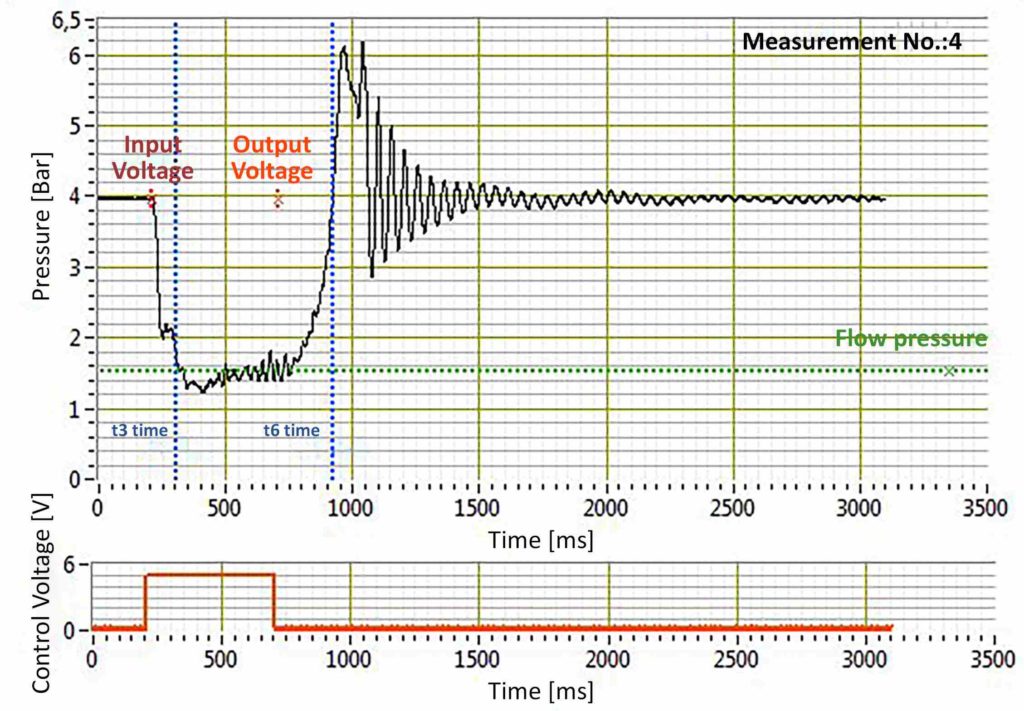

Bürkert’s Type 6213 has a soft-close feature, which means that the opening and closing sequences are gradual, compared to a standard direct acting solenoid valve. This minimises any pressure rise and has been proven in a test that was conducted with a competitor’s valve.

With a 4bar inlet pressure, there was almost 38bar observed when the competitor’s valve closed. This can have serious consequences for other pieces of equipment, such as pH probes, which may be designed with a maximum operating pressure of 10 bar.

In contrast, when the Type 6213 was closed the pressure increased to around 6 bar, well within the permissible operating pressures for other pieces of equipment.

When maintenance professionals discover these issues, customers need a solution quickly so Bürkert and its network of retailers have stock of the most common specifications to ensure same-day or next-day delivery.

With nominal diameters from 10mm to 40mm and a range of body and seal materials, the Type 6213 can also be specified for a wide range of applications beyond potable water.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer