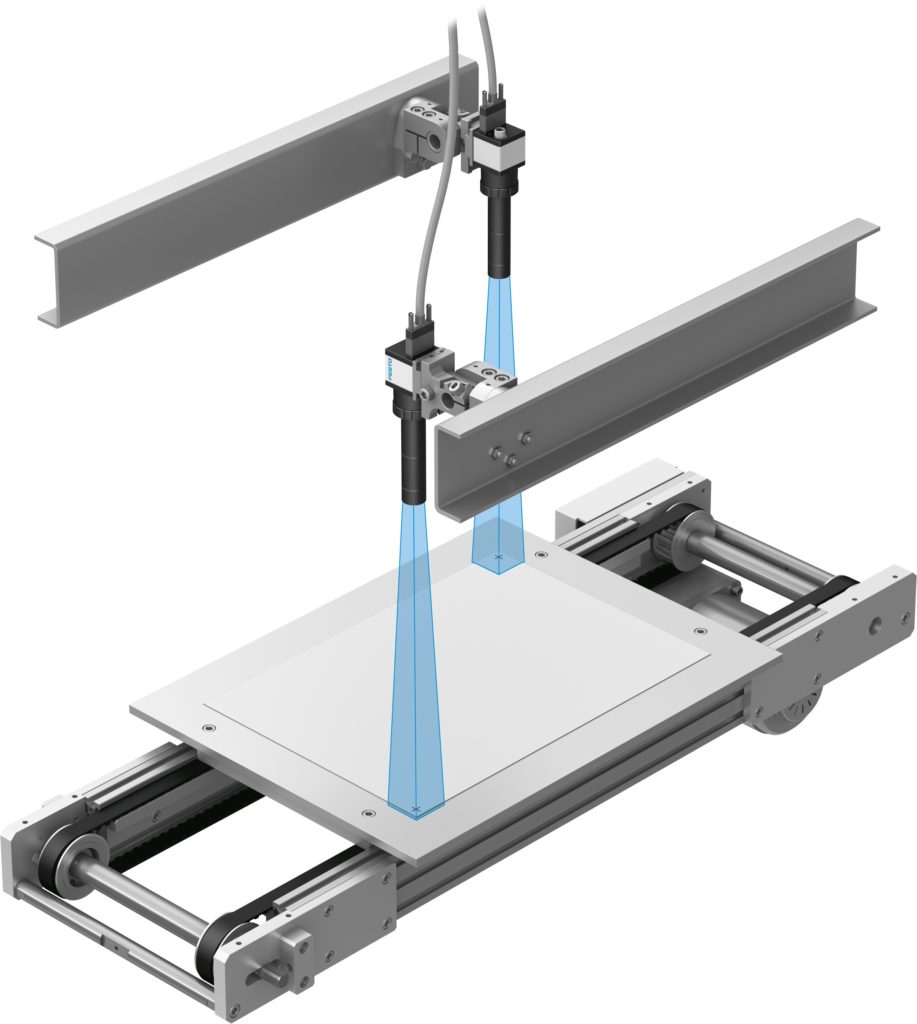

The new SBRD smart camera from industrial automation specialists Festo lies at the heart of an intuitive image processing system that opens up new perspectives in automation and robot technology.

High-resolution cameras and a powerful controller form the core of the SBRD smart camera system, while high-performance image-processing software delivers fast, process-reliable results.

Lightweight and compact in design, the system makes carrying out inspections from several perspectives or with a large field of view very simple and intuitive.

Equipped with two camera interfaces, the fanless remote head controller is suitable for multi-camera tasks and has a powerful dual-core processor and PROFINET communication. The high-speed, high-resolution USB cameras deliver monochrome or colour images with a resolution of between 1.3 and 5 megapixels.

Configurable inspection

The Camera Configuration Studio (CCS) image processing software is simple to use and allows inspection parameters to be tailored to individual project requirements.

Users can configure inspection programs and define, log and adjust processes from image recording to input and output parameters – and even simulate them on the PC before starting.

The software enables images to be processed in a very stable way by using image analysis and image lists instead of individual images.

To achieve this, users simply select and record different sample pieces. They can then define what exactly needs to be analysed and how this should be done.

The tolerance ranges are based on the results data of the recorded images. Subsequent manual adjustments are also possible.

Additional tool for pick & place solutions

A further add-on option is the CCS xRun tool, which enables test tools to be parameterised quickly. With the help of this tool, users only need to configure the settings once.

The system then automatically applies these to all objects detected. This makes program development and maintenance easier and keeps the program structure very simple.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer