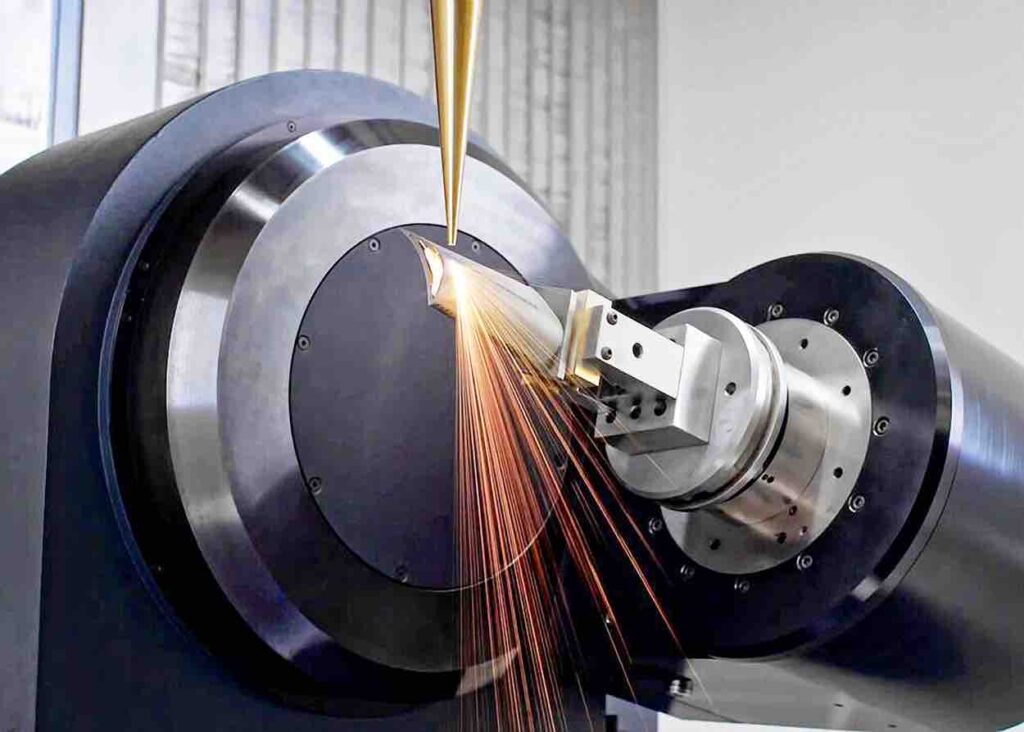

For rapid, efficient production of cooling air holes in gas turbine components such as guide vanes, blades, buckets, combustors and heat shields, DMG MORI has introduced the new LASERTEC 160 PowerDrill and its smaller counterpart, the LASERTEC 100 PowerDrill.

Intended for manufacturers in the aerospace, power generation and other industries, the machines have a small footprint yet offer a large working envelope, making them ideal for companies that are short of space on the shop floor.

To meet the increasingly high accuracy requirements in the target industries, the new 5-axis drilling machines are based on a modular, moving-column design. The column moves in the X and Y axes, providing rigidity for high accuracy machining throughout the entire working volume. It is 1,600 x 1,000 x 1,000mm for the larger model and 1,000 x 1,000 x 1,000mm for the smaller, respective footprints being 14.7sq m and 12.7sq m.

A swivel axis for the tool and a rotary axis for the workpiece, or alternatively a swivelling rotary axis for the workpiece, together with different table variants, offer the right kinematics for every application, especially in bucket and combustor machining. Depending on the application, the machines are available with different space-saving fibre lasers rated at 9kW to 23kW, as well as in the PowerShape machine version for shaped-hole machining. With variable collimation, the laser’s focus spot size can be changed during processing without manual intervention.

Linear drives in the X and Y axes, with acceleration of 7m/s² and rapid traverse up to 90m/min, ensure high dynamics. In combination with a newly developed laser control, up to 500 holes per second can be produced.

The machines have other advanced features such as shoot-through detection, capacitive distance sensors, water-cooled motors, linear guideways and ballscrews, an optional tool changer for different processing heads, automatic drill position detection and a camera integrated into the laser optics.

Lasersoft PowerDrill software, which was developed in-house and has proven itself over many years, supports all jobs with a high level of user-friendliness and ease of programming. DMG MORI’s proprietary, app-based interface CELOS and the powerful SIEMENS 840D solutionline control ensure ease of use and high process reliability.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer